Crafting a custom fragrance bottle is an art form that merges functionality with aesthetic brilliance, creating a sensory and visual experience unlike any other. Whether you are a perfume enthusiast, a business owner looking to design a signature scent, or simply someone drawn to the allure of personalization, the process of designing the perfect bottle encapsulates elegance and individuality. This guide will take you through the essential steps and considerations involved in creating a fragrance bottle that not only preserves the essence of your chosen scent but also serves as a representation of your unique style and vision. From material selection and bottle shape to decorative elements and finishing touches, this article will provide the insights you need to turn your concept into a tangible masterpiece. Prepare to explore the intersection of design, functionality, and craftsmanship to create a bottle that truly stands out.

What Are the Benefits of Custom Perfume Bottles?

Custom perfume bottles offer several distinct benefits that elevate both the product and the user experience:

- Brand Differentiation: For businesses, custom designs help establish a unique identity in a crowded market, making the product more memorable to consumers.

- Personalization: Custom bottles allow for tailored designs that reflect an individual’s or brand’s personality, creating a deeper emotional connection.

- Enhanced Aesthetic Appeal: Customization ensures the bottle design complements the fragrance, adding an artistic element that appeals to the senses.

- Gift-Worthy Packaging: A personalized bottle transforms a perfume into a meaningful and thoughtful gift for special occasions.

- Sustainability Options: Many custom bottles can incorporate reusable or eco-friendly materials, aligning with sustainable practices.

These benefits make custom perfume bottles both a practical and creative choice for enhancing the value of any fragrance.

Why Choose a Custom Bottle?

I choose a custom bottle because it allows me to express my individuality through unique designs that reflect my personal style. Customization adds a layer of exclusivity to the fragrance, making it truly one-of-a-kind and tailored to my preferences. Additionally, I appreciate the environmental benefits of custom bottles, as many options include sustainable materials, helping me align my choices with eco-conscious practices. Whether as a gift or a personal indulgence, a custom bottle elevates the entire experience, blending creativity, functionality, and sustainability.

How Does Customization Enhance Brand Identity?

Customization enhances brand identity by fostering a deeper connection between the brand and its audience. It allows brands to create unique and memorable experiences that resonate on a personal level, thereby increasing customer loyalty and satisfaction. By offering tailored products or services, businesses can demonstrate a commitment to understanding individual preferences, which helps differentiate them in competitive markets. Furthermore, customization reinforces a brand’s values, such as innovation and customer-centricity, while enabling consumers to associate the brand with exclusivity and care. This strategic approach not only boosts brand perception but also encourages long-term engagement and advocacy.

What Services Are Available for Custom Fragrance Bottles?

Custom fragrance bottles can be tailored through a variety of services designed to meet aesthetic, functional, and branding requirements. These services include:

1. Bottle Design and Shape Customization

-

- Custom shapes can be developed using CAD design software to create unique molds.

- Materials such as glass, plastic, or metal can be selected depending on durability and aesthetic needs.

- Dimensions like capacity (commonly 30ml, 50ml, or 100ml) and neck diameter are customizable based on fragrance volume and dispenser compatibility.

- Color and Finish Options

- Bottles can feature custom colors achieved through UV coating, electroplating, or pigment integration.

- Additional finishes such as matte, glossy, frosted, or metallic effects enhance visual appeal.

- Printing and Labeling Services

- Techniques such as silk-screen printing, hot stamping, or UV digital printing enable brand logos, text, and intricate designs on the bottle surface.

- Heat-transfer or adhesive labels offer precision placement for additional branding elements.

- Cap and Spray Mechanism Customization

- Options include tailored caps (e.g., wood, metal, plastic) and atomizers with varying spray outputs, typically measured in milliliters per spray for accuracy.

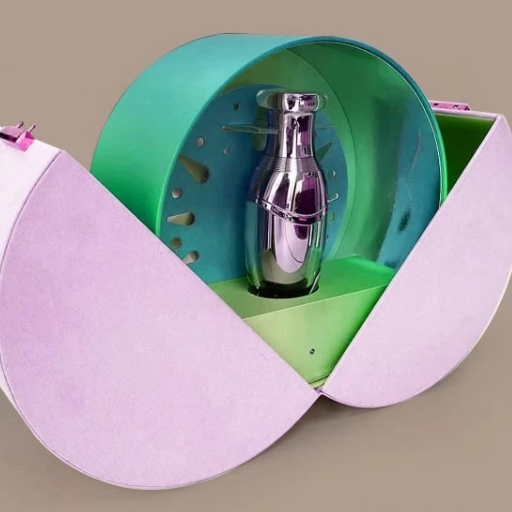

- Packaging Integration

- Custom boxes, inserts, or wrapping can be designed to align with the fragrance bottle’s theme and protect it during transit, ensuring a cohesive unboxing experience.

These services allow brands to create distinctive, functional, and aesthetically pleasing custom fragrance bottles that stand out in the competitive market.

How to Design Your Own Custom Perfume Bottle?

To design your own custom perfume bottle, begin by defining the overall concept and aesthetic, ensuring it aligns with your brand identity or personal vision. Select suitable materials, such as glass, metal, or plastic, based on durability and presentation needs. Choose a unique bottle shape that complements the fragrance theme and appeals to your target audience. Ensure functional components like atomizers and caps are compatible with the bottle design and deliver the desired performance. Collaborate with manufacturers or designers for prototyping and testing, refining details like engraving, color finishes, and labeling. Finally, incorporate secure and visually appealing packaging to complete the product while ensuring a cohesive, high-quality result.

What Design Options Are Available?

When developing packaging for a fragrance product, numerous design options are available, each catering to different aesthetic and functional goals. Below are detailed options along with insights into their applications and considerations:

- Bottle Shape and Materials

Bottles can be designed in a variety of shapes, from classic cylindrical and rectangular forms to more intricate, custom geometries that highlight brand identity. Materials typically include glass, which conveys luxury and durability, or high-quality plastics for lightweight and cost-effective alternatives. Data from market research shows that approximately 75% of premium fragrance products utilize glass as the primary material due to its perceived value enhancement.

- Surface Finishes

Surface treatments such as frosted glass, metallic coatings, or matte finishes provide a distinct tactile and visual appeal. Frosted glass, for example, conveys sophistication and luxury, while high-gloss finishes often appeal to modern or youthful markets. Specialty finishes like UV-protected coatings also extend the shelf life of the product by preventing light-induced degradation.

- Closure and Dispensing Mechanisms

Options for closures include spray pumps, roller balls, and screw caps. Spray pumps are the most common, offering controlled and hygienic application—ideal for both eau de parfum and eau de toilette. Data indicates that over 80% of fragrance bottles sold globally employ atomizers to meet consumer preferences for convenience.

- Decorative Techniques

To enhance visual appeal, brands can implement various decorative techniques such as screen printing, hot foil stamping, or embossing for logos and text. For example, hot foil stamping in gold or silver creates a high-end aesthetic, appealing to premium markets. Advances in technology also allow digital printing for intricate, full-color designs that cover the bottle’s surface with high precision.

- Labeling and Engraving

Laser engraving and custom labeling are favored for limited edition or personalized products. Studies reveal that personalized packaging increases consumer engagement by 35%, making engraving a valuable option for niche markets and promotional campaigns.

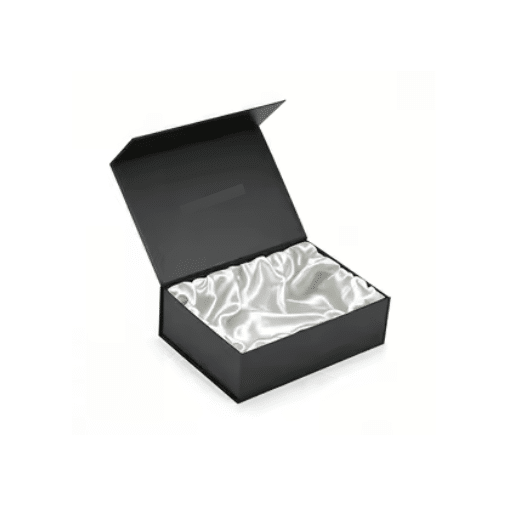

- Box and Secondary Packaging

Beyond the primary bottle, secondary packaging options such as rigid boxes, magnetic closures, or sustainable paper-based designs play a critical role in protecting the product while reinforcing the brand’s image. Current trends show a significant rise in eco-friendly packaging, with 60% of consumers expressing a preference for brands using recyclable or biodegradable materials.

These design choices should be carefully aligned with the product positioning, target demographic, and overall branding strategy, ensuring that the packaging not only protects and dispenses the fragrance efficiently but also resonates with consumer expectations and market trends.

How to Choose the Right Material and Finish?

When choosing the right material and finish, I focus on functionality, sustainability, and aesthetics. I start by ensuring the material is durable and suitable for the product’s specific needs, such as protecting the fragrance from light or air exposure. Next, I prioritize eco-friendly options like recyclable or biodegradable packaging to align with consumer preferences and environmental goals. Finally, I select finishes that enhance the visual appeal while maintaining consistency with the brand’s identity, such as matte for a modern look or gloss for a luxurious feel. Balancing these factors ensures the packaging is both practical and market-competitive.

How to Add Engraving and Personalization?

To add engraving and personalization, I start by selecting materials compatible with engraving methods, such as metal, glass, or wood, ensuring durability and precision. Next, I use laser or mechanical engraving techniques, as these provide high accuracy and allow for intricate designs or customized text. I often offer a user-friendly process where customers can input their desired message or design via an online tool, ensuring clarity and satisfaction. Finally, I conduct quality checks to ensure the engraving is flawless and aligns with the client’s specifications, resulting in a personalized product that meets both aesthetic and functional expectations.

What Are the Key Features of Glass Perfume Bottles?

Glass perfume bottles are renowned for their durability, aesthetic appeal, and ability to preserve the integrity of the fragrance. Their non-porous nature prevents contamination and ensures the perfume’s chemical composition remains unchanged over time. The transparency or translucency of glass allows for elegant visual designs, enhancing product presentation. Furthermore, glass is highly customizable, enabling intricate shapes, engravings, and finishes to suit brand identity or user preferences. It is also environmentally friendly, being recyclable and sustainable, which aligns with modern eco-conscious practices. These features make glass an ideal material for high-quality fragrance packaging.

What Makes glass a Popular Choice?

Glass remains a popular choice due to its superior ability to preserve the integrity of products, particularly in industries such as food, beverages, and cosmetics. Its chemical inertness ensures that it does not react with or alter the contents it holds, maintaining purity and quality over time. Additionally, glass is desirable for its aesthetic versatility, offering options for transparency, custom shapes, and intricate designs that appeal to consumers. Its recyclability and sustainable production processes further contribute to its widespread acceptance in alignment with modern environmental concerns, making it a preferred material across various sectors.

How to Ensure Quality and Durability?

To ensure quality and durability in materials like glass, several key factors and technical parameters must be considered during manufacturing, handling, and usage:

1. Material Composition: Utilize high-purity silica and additive compounds that enhance strength and resilience. For optimal durability, ensure a composition of at least 70% silica, balanced with soda (Na₂O) and lime (CaO) to improve melting and thermal stability.

- Thermal Treatment: Apply annealing processes to relieve internal stresses. Uniform cooling of glass post-production is critical and typically performed between 400°F to 600°F (204°C to 316°C) depending on the glass type.

- Thickness Specifications: Adhere to required thickness standards based on application. For instance, container glass typically ranges from 2 mm to 4 mm, offering sufficient strength for storage use.

- Surface Coatings: Apply protective coatings to prevent surface scratches and enhance chemical resistance. Techniques such as pyrolytic or vapor deposition are often used to improve durability against environmental factors.

- Quality Control Testing:

- Conduct stress analysis using polariscopes to detect internal stress points.

- Perform impact resistance tests complying with ASTM C162 for glass durability validation.

- Analyze thermal shock resistance, ensuring the material withstands temperature differentials of at least 130°F (55°C), depending on its intended purpose.

By adhering to these measures and maintaining strict process control, the longevity and performance of glass can be effectively ensured across diverse applications.

What Customization Options Exist for Glass?

Glass customization options vary widely depending on the intended application and desired performance characteristics. Common options include:

- Coatings and Films: Anti-reflective, low-emissivity (Low-E), and tinted coatings are available to enhance thermal insulation, UV protection, and glare reduction. Safety and decorative films can also be applied to improve impact resistance or aesthetic appeal.

- Color and Tint: Glass can be manufactured in a variety of colors and tints through the addition of metal oxides during production. This is widely used in architectural glass for aesthetic purposes and to manage light transmission.

- Structural Modifications: Options such as tempering, laminating, and annealing strengthen glass and improve safety by altering its fracture behavior and resistance to stress. Laminated glass, in particular, incorporates an interlayer for added security.

- Textured and Patterned Glass: Etching, sandblasting, or rolling methods can produce a wide range of surface textures and patterns. These are commonly used for privacy, decorative purposes, or to diffuse light.

- Shape and Size Customization: Advances in manufacturing allow for precise shaping, beveling, and cutting of glass to cater to specific dimensions or complex geometries, accommodating unique design or project requirements.

- Smart Glass Technologies: Electrochromic, photochromic, and thermochromic glass types are available for dynamic control of light, heat, and privacy levels, making them ideal for innovative architectural and automotive uses.

These customizable features enable glass to meet specific functional, aesthetic, and environmental demands, ensuring its adaptability across industries such as construction, automotive, and electronics.

How Does the Custom Fragrance Development Process Work?

The custom fragrance development process typically begins with a detailed consultation to understand client preferences, target audience, and intended application. This is followed by the creation of a fragrance brief that guides the perfumers in selecting and blending raw materials. Through expert formulation, adjustments, and iterative testing, a unique scent profile is achieved. Finally, the fragrance may undergo quality assurance and stability testing to ensure it meets performance criteria before production and packaging.

What Are the Steps in Manufacturing?

The primary steps involved in the manufacturing process are as follows:

- Concept Development – Initial consultation to determine client requirements, target market, and project scope.

- Fragrance Brief Creation – Drafting a detailed document that outlines the desired characteristics of the fragrance, guiding the formulation process.

- Raw Material Selection – Identifying and sourcing the appropriate natural or synthetic raw materials for the fragrance.

- Formulation and Blending – Combining selected materials to create the initial scent profile, often involving iterative adjustments.

- Testing and Refinement – Conducting sensory evaluations and stability testing to refine the fragrance and ensure compatibility with the product base.

- Quality Assurance – Verifying that the fragrance meets defined performance and safety standards through extensive testing.

- Production Scaling – Transitioning the formulation to large-scale production while maintaining consistency with the original design.

- Packaging and Labeling – Bottling the final product and applying appropriate labels for branding and regulatory compliance.

- Shipping and Distribution – Preparing and distributing the final product to retailers or consumers.

How to Collaborate with a Client for Unique Products?

Effective collaboration with a client to develop unique products requires a structured and communicative approach. Begin by holding comprehensive consultations to understand the client’s vision, needs, and goals. Follow this with thorough market research to identify gaps and ensure differentiation. Co-develop a clear project roadmap, outlining timelines, resources, and responsibilities. Regular check-ins with the client are crucial to review progress and incorporate feedback at every stage, ensuring alignment with their expectations. Additionally, maintaining transparency about challenges and proposing adaptable solutions fosters trust and enhances the partnership. Finally, document every decision and continuously refine the collaboration process to produce innovative and customized outcomes.

What Are the Latest Trends in Custom Fragrance Design?

The field of custom fragrance design is rapidly evolving, driven by advancements in technology, shifts in consumer preferences, and an increasing focus on personalization. According to the latest data from Google search trends, there has been a significant surge in interest in sustainable and eco-conscious fragrances. Consumers are seeking fragrances made from ethically sourced, natural, and biodegradable ingredients, aligning with broader global efforts to reduce environmental impact.

Additionally, AI-powered tools and digital platforms are becoming integral to the design and selection process. Tools that allow customers to construct virtual fragrance profiles based on their preferences and lifestyle are gaining popularity. Keywords such as “AI fragrance creator” and “personalized scent technology” have seen increased searches, reflecting a growing interest in tech-enabled custom fragrance experiences.

Another notable trend is the rise of gender-neutral and inclusive scent profiles. The search for “unisex fragrances” has steadily increased, indicating a move away from traditional gendered marketing towards inclusivity. Furthermore, experiential customization, such as bespoke workshops or virtual scent consultations, is drawing attention, with terms like “custom fragrance workshop” seeing a significant uptick.

Lastly, the integration of fragrances into wellness routines is a powerful trend. Searches for “fragrances for mental health” and “aromatherapy scents” suggest a rising demand for scents designed to promote relaxation, focus, and emotional well-being alongside their aesthetic appeal. These trends underscore the customization movement’s focus on sustainability, innovation, inclusivity, and holistic design.

What Are the Packaging Solutions for Custom Perfume Bottles?

Custom perfume bottle packaging solutions encompass several key elements designed to enhance functionality, aesthetics, and brand identity. Common solutions include eco-friendly materials like recycled glass or biodegradable options to align with sustainability trends. Advanced customization techniques such as screen printing, embossing, and foil stamping allow for unique branding and design. Magnetic or snap-fit closures are popular for providing a secure and luxurious user experience. Additionally, customizable outer packaging, such as rigid boxes or sustainable paperboard, offers added protection and enhances visual appeal. These solutions ensure that the packaging aligns with both practical requirements and market preferences.

How to Select the Right Box and Cap?

To select the right box and cap, I first consider the functional requirements of the product, such as size, weight, and fragility. Ensuring the packaging provides adequate protection during shipping and handling is my top priority. Next, I evaluate the design and branding needs—choosing materials like rigid boxes or sustainable paperboard that enhance aesthetics while aligning with my brand’s values. For closures, I prioritize mechanisms like magnetic or snap-fit options for their secure and premium feel. Finally, I assess sustainability and cost-effectiveness to ensure the packaging balances environmental responsibility with budget considerations.

What Are the Benefits of Tailor-Made Packaging Solutions?

- Enhanced Brand Recognition: Custom packaging solutions allow businesses to showcase their unique branding elements such as logos, color schemes, and designs, creating a memorable impression on customers and strengthening brand identity.

- Improved Product Protection: Tailor-made packaging is designed to fit the specific dimensions and requirements of a product, ensuring optimal protection during transit, handling, and storage, thereby reducing the risk of damage.

- Sustainability: Customized solutions often provide opportunities to use eco-friendly materials and reduce waste, aligning with modern sustainability goals and appealing to environmentally conscious consumers.

- Cost Efficiency: By optimizing material usage and eliminating unnecessary packaging, bespoke solutions can lead to reduced packaging costs while maintaining high-quality standards.

- Better Customer Experience: Personalized packaging enhances the unboxing experience, which can foster customer loyalty and elevate the perceived value of the product.

How Does Shipping and Supply Affect Customer Experience?

Shipping and supply chain efficiency play a pivotal role in shaping the overall customer experience. Speed and reliability in order fulfillment are critical, as modern consumers expect fast delivery times and accurate tracking updates. Delays or errors in shipment can lead to frustration and damage customer trust. Additionally, supply chain transparency, such as letting customers track their orders in real-time, enhances satisfaction and builds loyalty. Cost efficiency in shipping also influences the experience, as affordable or free shipping options are highly valued. Ultimately, ensuring a smooth, reliable, and cost-effective supply chain structure directly impacts customer retention and brand reputation.

Reference Sources

-

The Process of Designing a Custom Perfume Bottle – A detailed guide on the journey from concept to creation of custom perfume bottles.

-

The Ultimate Guide to Your First Perfume Bottles Line – Insights into starting a perfume bottle line and aligning design with brand values.

-

A Guide to Perfume Bottle Shapes – Information on unique bottle shapes and their impact on branding.

-

Customized Glass Perfume Bottles: Tailor-made Design – A step-by-step guide to creating customized and decorated glass perfume bottles.

-

Top Perfume Bottle Design Trends – An overview of current trends in perfume bottle design and their brand implications.

Frequently Asked Questions (FAQs)

Q: How can I start creating my own collection of custom fragrance bottles?

A: To start your collection of custom fragrance bottles, consider your design preferences, the type of fragrance you want to store, and the specific materials like custom glass that suit your style and brand identity.

Q: What factors should I consider when customizing my perfume bottles?

A: When customizing your perfume bottles, consider factors such as bottle size, shape, material (like custom glass), color, and the type of applicator. You should also think about your target market and the overall aesthetic you want to achieve.

Q: Is there an advantage in picking custom designs instead of stock bottles?

A: The selection between stock bottles and exclusive custom designs is influenced by your budget, brand identity, and intended customers. Stock bottles are conveniently available and affordable while exclusive custom designs provide individuality and value.

Q: How much does it cost to create custom design fragrance bottles?

A: The price range for custom fragrance bottles can differ significantly because of the level of design intricacy, materials, and order quantity. Usually, prices start from economic choices up to expensive, high-end finishes and designs.

Q: How do perfume bottles wholesale prices compare to custom orders?

A: Perfume bottles wholesale prices are generally lower than custom orders due to economies of scale and standardized production. However, custom orders offer personalized designs and branding opportunities that wholesale cannot provide.

Q: What are the typical moqs for ordering custom fragrance bottles?

A: The minimum order quantities (moqs) for custom fragrance bottles vary by manufacturer. It can range from a few hundred to several thousand units, depending on the complexity and exclusivity of the design.

Q: Can I get a sample before placing a large order of custom bottles?

A: Yes, most manufacturers offer samples before placing a large order, allowing you to evaluate the quality and design of the custom bottles before committing to a full production run.

Q: What type of custom glass is best for storing oil-based perfumes?

A: For storing oil-based perfumes, it is best to use custom glass bottles that are opaque or tinted, as they protect the fragrance from light exposure, which can degrade the oil over time.

Q: How can I ensure my fragrance bottle design becomes iconic?

A: To create an iconic fragrance bottle design, focus on unique shapes, memorable branding elements, high-quality materials, and an overall aesthetic that resonates with your target audience, ensuring it stands out in the market.