The design of a perfume bottle is much more than a mere container; it is a visual and tactile extension of the fragrance it holds. The intricate craftsmanship of glass perfume bottles merges functionality with artistic expression, making each piece unique and captivating. This article will explore the various aspects of customizing perfume bottles, offering insights into the materials, design techniques, and personalization options that elevate them to works of art. From the historical significance of glass bottle craftsmanship to the modern trends influencing bottle aesthetics, we aim to provide a comprehensive framework to guide you through the fascinating world of bespoke perfume bottle design. Whether you’re a perfume enthusiast, a designer, or a brand looking to stand out, this in-depth discussion will uncover the nuances that make a perfume bottle extraordinary.

How to Customize Perfume Bottles for a Unique Fragrance?

- Choose Distinct Shapes and Materials

Opt for bottle shapes and materials that align with the essence of the fragrance. For example, use rounded designs for softer scents or angular designs for bold fragrances. Materials like glass, crystal, or eco-friendly options can convey luxury or sustainability.

- Personalize with Custom Labeling

Add unique branding elements such as engraved logos, embossed patterns, or specialized typography. Incorporate minimalistic or elaborate designs that resonate with the intended audience.

- Use Special Finishes

Coatings like frosted or metallic finishes, gradients, or transparent effects can enhance the visual appeal. These finishes can complement the fragrance’s theme and improve shelf presence.

- Integrate Functional Enhancements

Custom caps, spray heads, or decorative closures can add practicality and style. Consider features like magnetic closures or intricate designs for an elevated finish.

- Collaborate with Skilled Designers

Work with experienced packaging designers who understand the interplay between aesthetics and functionality. A professional touch ensures the design effectively represents the brand’s identity.

What are the Steps to Create a Custom Perfume Bottle?

Steps to Create a Custom Perfume Bottle

- Concept Development and Market Research

Begin by defining the design concept aligned with your brand identity and target audience. Conduct market research to identify current trends, preferred bottle shapes, and functional requirements. Analyze competitors’ designs to ensure your concept is both unique and practical.

- Sketch and 3D Modeling

Collaborate with professional designers to sketch initial ideas, incorporating desired shapes, decorative elements, and functional features. Use CAD (Computer-Aided Design) software to develop precise 3D models that consider technical parameters such as volume (typically 30ml, 50ml, or 100ml for standard perfumes) and neck finish size (commonly between 15mm and 18mm for spray compatibility).

- Material Selection

Choose appropriate materials for the bottle, such as glass, acrylic, or metal. Glass is the most common material due to its durability and resistance to chemical reactions with perfume. Consider thickness specifications (e.g., 3–5mm for bottle walls) to enhance strength while ensuring a high-quality aesthetic.

- Mold Design and Prototyping

Develop molds for manufacturing based on the finalized 3D designs. Create prototypes using 3D printing or other rapid prototyping techniques to test the shape, size, and feel. Ensure the prototype meets the required specifications, such as weight (normally 200–400g depending on size) and user ergonomics.

- Surface Treatment and Decoration

Apply surface treatments like polishing, frosting, or coating to achieve the desired finish. Incorporate decorative elements like UV printing, screen printing, or hot-stamping for logos and artwork. Use Pantone color matching systems to ensure color consistency across designs.

- Functional Feature Integration

Select bottle closures and dispensers (e.g., screw caps or spray pumps) that match the neck size and aesthetic of the bottle. Test closures for compatibility to avoid leaks and ensure smooth operation. For spray pumps, ensure atomization parameters meet industry standards (e.g., 0.10–0.15ml per spray).

- Quality Assurance and Testing

Perform rigorous testing for durability, leak prevention, and resistance to environmental conditions such as UV exposure and temperature variations. Quality control parameters should include drop tests (from a typical height of 1.2m), pressure resistance, and cap retention testing.

- Mass Production and Packaging

Once the design passes all testing stages, proceed to mass production. Work with suppliers to ensure consistency in manufacturing. Develop secondary packaging to complement the bottle design, ensuring functionality and aesthetic appeal for the final product.

By following these steps, you can efficiently create a custom perfume bottle that aligns with brand values, customer expectations, and technical requirements.

How Does Engraving Enhance a Perfume Bottle?

Engraving enhances a perfume bottle by adding a layer of sophistication, personalization, and brand distinction. Through precise techniques such as laser etching or mechanical engraving, detailed logos, intricate patterns, or bespoke messages can be permanently inscribed onto the bottle. This not only elevates the perceived value of the product but also strengthens brand identity by creating a unique, luxurious design. Additionally, engraved elements provide a tactile experience, increasing consumer engagement and leaving a memorable impression. Engraving is also durable, ensuring that the design remains intact over time, even with regular handling, thus increasing the product’s longevity and appeal.

What Role Does Design Play in Customizing Bottles?

Design plays a crucial role in customizing bottles by merging functionality with aesthetics to create a product that stands out. From selecting the right materials and shapes to integrating detailed finishes like engraving or unique color schemes, every design choice impacts how the bottle is perceived and used. A well-thought-out design not only enhances the visual appeal but also aligns with the brand’s identity, ensuring the bottle resonates with its target audience. By emphasizing durability and user experience, design elevates both practicality and market competitiveness.

What Are the Best Packaging Solutions for Glass Perfume Bottles?

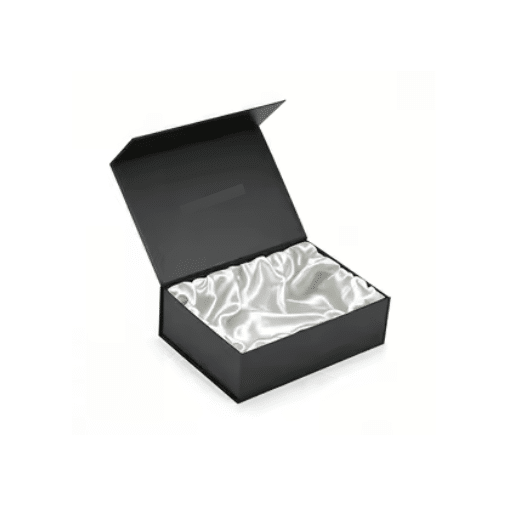

When selecting the best packaging solutions for glass perfume bottles, it is crucial to prioritize both protection and aesthetic appeal. Protective packaging, such as foam inserts, molded pulp, or soft cushioning materials, ensures the bottles remain intact during transportation and handling. Outer packaging, like sturdy cardboard boxes or rigid containers, provides an additional layer of safety. To enhance the visual aspect, customized designs, vibrant printing, and branded labels can reinforce a premium look while aligning with the overall brand identity. Sustainable options, such as recyclable or biodegradable materials, are increasingly favored, appealing to eco-conscious consumers. By combining functionality, durability, and design, the chosen packaging solution effectively safeguards the product while creating a memorable consumer experience.

How Can Packaging Design Elevate Your Brand?

Effective packaging design can elevate your brand by enhancing consumer perception, driving purchasing decisions, and reinforcing brand values. Technically, the following parameters play a crucial role in this process:

- Material Composition: Utilize materials that align with your brand’s ethos, such as premium cardboard, glass, or eco-friendly alternatives like biodegradable plastics, to emphasize quality and sustainability.

- Structural Design: Ensure ergonomic and durable packaging to provide ease of handling, protection during transport, and storage efficiency. Parameters like thickness (e.g., 300-350 GSM for cartons) and structural integrity testing (e.g., drop or compression tests) are essential.

- Visual Elements: Incorporate high-resolution printing (at least 300 DPI) for crisp graphics, color schemes compliant with your brand guidelines (e.g., Pantone Matching System), and finishes such as matte, gloss, or embossing to create a distinctive impression.

- Functional Features: Integrate features like resealable closures, tamper-evidence, or QR codes for added consumer convenience and security.

- Sustainability Metrics: Highlight the recyclable content ratio (e.g., 80% post-consumer materials) or carbon footprint reductions to demonstrate your commitment to environmental responsibility.

By carefully optimizing these technical and design parameters, your packaging not only secures the product but also communicates your brand’s message effectively to establish a lasting connection with consumers.

Why Choose Luxury Packaging for Your Perfume?

Luxury packaging for perfume is essential because it embodies the sophistication and exclusivity of the fragrance itself. It elevates the sensory experience, as high-quality materials and intricate designs communicate prestige and attention to detail. Beyond aesthetics, luxury packaging protects the fragrance effectively, ensuring it remains in perfect condition. Most importantly, it creates a strong first impression and emotional connection with consumers, turning the packaging into a powerful extension of the brand’s identity.

What Are the Latest Innovations in Custom Perfume Bottles?

Latest Innovations in Custom Perfume Bottles

Recent advancements in custom perfume bottles focus on sustainability, technology, and unique design elements. Sustainable packaging is at the forefront, with the use of recycled glass, biodegradable materials, and refillable bottle systems gaining popularity to reduce environmental impact. Smart technology is also making its way into the industry, such as NFC-enabled bottles that provide product information or authentication via smartphones. Additionally, brands are pushing boundaries with innovative shapes, textures, and artistic collaborations, creating visually striking designs that enhance brand identity and consumer engagement. These innovations reflect a shift toward combining functionality with creativity and environmental responsibility.

How Are Custom Glass Perfume Bottles Manufactured?

Custom glass perfume bottles are manufactured through a detailed and precise process that combines traditional glassmaking techniques with modern technology. First, the design phase involves creating detailed sketches and 3D models to visualize the desired shape, size, and ornamental details. Once the design is approved, molds are crafted, often from metal, to shape the molten glass. The glass, made from materials like silica sand, soda ash, and limestone, is heated at extremely high temperatures until it liquefies. It is then blown or pressed into the molds to achieve the exact design specifications. After shaping, the bottles undergo annealing, a process that slowly cools the glass to remove internal stress and enhance durability. Additional steps include polishing, engraving, or applying decorative finishes like coloring, frosting, or metallic accents. Finally, quality control inspections ensure each bottle meets the highest standards before packaging and delivery.

What Makes a Fragrance Bottle Innovative?

Innovation in a fragrance bottle stems from a combination of design, functionality, and sustainability. From my perspective, it’s about creating a visual identity that captures the essence of the fragrance while integrating cutting-edge materials or technologies. Unique shapes, artistic details, and smart features such as refillable systems or atomizer innovations all contribute to its appeal. Additionally, the use of eco-friendly materials or practices, like recycled glass or minimalistic yet durable designs, ensures the bottle aligns with modern sustainability standards.

How Do Refillable Perfume Bottles Impact the Perfume Industry?

Refillable perfume bottles are transforming the perfume industry by addressing both environmental sustainability and consumer demand for practicality. By reducing single-use packaging, these bottles significantly cut down on waste and support eco-conscious brand initiatives. Many manufacturers have embraced this model by implementing refill stations or eco-friendly refills, appealing to environmentally aware consumers. Additionally, refillable designs often lower long-term costs for customers, enhancing brand loyalty. From an operational perspective, this approach promotes resource efficiency, as brands can reduce the production of excess packaging materials. Overall, refillable perfume bottles represent a key innovation driving the industry’s shift towards sustainable and customer-centered practices.

How Do Luxury Perfume Brands Utilize Custom Perfume Bottles?

Luxury perfume brands utilize custom perfume bottles to reinforce their brand identity, enhance customer experience, and convey a sense of exclusivity. These bottles are often designed with unique shapes, intricate details, and premium materials to reflect the values and story of the brand. Additionally, customized packaging serves as an effective marketing tool, making the product instantly recognizable and more appealing on store shelves or in advertisements. By prioritizing craftsmanship and aesthetic appeal, brands further establish their position in the competitive luxury market while creating a lasting impression on consumers.

What is the Importance of Branding in Perfume Bottle Design?

Branding in perfume bottle design is critically important because it communicates the essence of the fragrance and sets it apart in a saturated market. A well-branded bottle must blend aesthetic appeal with storytelling, creating an emotional connection with the consumer while maintaining functional excellence. Key technical parameters to consider include the material (such as high-quality glass for durability and a premium feel), ergonomic shape for ease of handling, coloration or transparency to reflect fragrance characteristics, and innovative closures to ensure product integrity. These aspects not only enhance the sensory experience but also reinforce brand identity and consumer loyalty in the competitive fragrance industry.

How Do Luxury Perfume Bottles Influence Consumer Perception?

Luxury perfume bottles significantly influence consumer perception by acting as a physical embodiment of the brand’s values, quality, and exclusivity. The design and craftsmanship of the bottle trigger emotional connections and convey a sense of sophistication, often persuading customers that the fragrance matches the prestige of its packaging. Key technical parameters include:

- Material: Utilization of high-grade materials such as glass, metal accents, or crystal integrates durability and elegance.

- Design and Shape: Unique, ergonomic shapes create a visual impact while ensuring practicality for everyday use.

- Color and Finish: Strategic use of opaque, translucent, or gradient finishes evokes specific themes or emotions tied to the fragrance.

- Closure Mechanism: Innovations like magnetic or precision-crafted closures promote product integrity and ease of use.

- Decorative Elements: Embellishments such as intricate engravings, textured surfaces, or metallic foiling enhance the luxury appeal.

When these factors are curated meticulously, luxury perfume bottles become more than containers—they serve as lasting statements of artistry and brand excellence.

What Are the Benefits of Tailor-Made Perfume Bottles?

Tailor-made perfume bottles offer distinct advantages that elevate both customer experience and brand identity. One of the primary benefits is brand personalization, as these bottles can be uniquely designed to reflect the brand’s story, ethos, or target market, ensuring a strong visual connection with customers. Additionally, enhanced customer engagement is achieved through bespoke packaging that resonates emotionally, fostering loyalty and perceived value. Another key advantage lies in product protection and functionality—customized bottles can be engineered to ensure optimal preservation of the fragrance while incorporating practical yet luxurious designs. Ultimately, tailor-made perfume bottles serve as a fusion of art and utility, setting premium brands apart in a competitive market.

What Are the Challenges in Manufacturing Custom Perfume Bottles?

Manufacturing custom perfume bottles involves several key challenges. First, the design complexity can increase production costs and time, especially when intricate details or unique shapes are required. Second, maintaining consistent quality across batches can be difficult due to the precision needed in molding and finishing processes. Third, sourcing specialized materials, such as high-grade glass or custom embellishments, can lead to supply chain constraints. Finally, ensuring compatibility with the fragrance, such as preventing chemical reactions between the glass and the formula, adds another layer of complexity. These factors make custom bottle production a highly meticulous process requiring careful planning and expertise.

How Does Mold Design Affect Perfume Bottle Production?

Mold design plays a critical role in the perfume bottle production process as it directly impacts the quality, functionality, and aesthetic of the final product. First, the mold determines the exact dimensions and structural integrity of the bottle, ensuring that it meets design specifications with minimal variability. Precision in mold design is necessary to maintain uniformity, especially for high-production volumes, and tolerances are typically maintained within ±0.15 mm to ±0.25 mm based on industry standards.

Second, the type of mold material significantly affects its performance and durability during manufacturing. Common materials include hardened steel alloys and beryllium copper, chosen for their high thermal conductivity and resistance to wear from molten glass or plastics. Using high-quality materials extends the mold’s lifespan and ensures consistent product quality over time.

Third, mold design needs to account for efficient heat dissipation and cooling to avoid defects such as warping or uneven surfaces. Precision cooling channels are often integrated into the mold to maintain optimal operating temperatures, with temperatures typically kept around 900°F to 1100°F (for glass) at the forming stage. These features enable faster production cycles while maintaining the structural clarity and smooth finish of the bottle.

Finally, mold design directly influences secondary features, such as neck finish, threading, and embossments, that contribute to functionality and branding. For instance, accurate neck dimensions are necessary for achieving leak-proof sealing with atomizers or caps, with tolerances in this area often held to ±0.1 mm. A poorly designed mold can lead to inconsistencies that compromise both aesthetic and functional aspects, leading to costly rework or defects.

Efficient mold design requires collaboration between engineers and designers, leveraging advanced computer-aided design (CAD) and simulation tools to optimize performance while minimizing production challenges.

What Are Common Issues in Glass Packaging?

Common Issues in Glass Packaging

Glass packaging, while aesthetically pleasing and chemically inert, can present a variety of challenges during production and use. Key issues include:

- Breakage and Brittleness

Glass is prone to breakage due to its brittle nature. Factors such as excessive wall thickness variations, improper annealing during manufacturing, or inadequate packaging during transportation can lead to cracking or shattering. An optimal wall thickness uniformity tolerance typically falls within ±0.2 mm to prevent stress concentration points. Additionally, thermal shock resistance is critical, with standard glass types like soda-lime glass able to withstand temperature changes between 30°C to 50°C per second under controlled conditions.

- Dimension and Tolerance Variability

Precise dimensional control is essential for compatibility with closures, fillers, and sealing systems. Deviations in neck diameter or thread pitches can lead to leaks or assembly issues, with typical tolerances for diameters ranging between ±0.15 mm to ±0.25 mm. These variations can be mitigated through advanced forming and inspection technologies such as automatic vision inspection systems during production.

- Surface Defects

Scratches, bubbles, and inclusions in the glass reduce structural integrity and visual appeal. Contaminants or improper furnace conditions can result in these flaws. Inspection systems are deployed to detect defects larger than 0.1 mm in size, ensuring a high-quality finish.

- Chemical Durability

Glass must resist reaction or degradation when in contact with its contents, especially for food and pharmaceutical packaging. Testing standards such as USP Type I requirements ensure that glass can withstand aggressive environments without leaching harmful substances.

Addressing these challenges efficiently requires stringent quality controls, advanced manufacturing technologies, and adherence to international standards, ensuring the durability and usability of glass packaging.

How Can Shipping Solutions Ensure Perfume Bottle Integrity?

Ensuring perfume bottle integrity during shipping involves implementing robust packaging solutions and adhering to specific technical standards. First, we focus on using high-quality, multi-layer protective materials such as corrugated cardboard with a minimum bursting strength of 200 psi. Each bottle is individually secured using custom inserts, such as molded foam or polyethylene, to absorb shocks and prevent movement. Second, cushioning layers must be added to mitigate the impact from drops or vibrations—ideally materials with a shock absorption capacity of at least 40 Gs per square inch. Additionally, cartons should be sealed with industrial-grade adhesive tape to avoid accidental openings. Finally, we conduct rigorous packaging tests, such as ISTA drop tests and compression tests, to verify impact resilience under various conditions. These measures together minimize the risk of damage throughout transit while maintaining the product’s aesthetic and structural integrity.

Reference Sources

-

Stoelzle Glass Group – Customized Glass Perfume Bottles: This source discusses the development of customized designs for perfumery and cosmetics.

-

Gozone Pack – Luxury Perfume Bottles: Offers insights into creating unique and luxurious custom glass perfume bottles.

-

Lalique – Art Perfume Crystal Bottles: Features artistic collaborations in designing crystal perfume bottles.

-

Uzone Packaging – The Process of Designing a Custom Perfume Bottle: Explores the journey from concept to creation of custom perfume bottles.

-

Packamor – Custom Perfume Bottles Branding and Labeling: Discusses branding, labeling, and the value of custom perfume bottles.

Frequently Asked Questions (FAQs)

Q: How can I create a custom fragrance in a unique perfume bottle?

A: To create a custom fragrance, you can start by selecting a perfume bottles wholesale supplier that offers a range of perfume glass bottles. This will allow you to choose a design that reflects your personal style. You can then work with a perfumer to develop a bespoke scent that complements your bottle design, making it a truly unique perfume.

Q: What are some decoration services available for customizing perfume bottles?

A: There is a list of decoration services to enhance your perfume bottle, including hot stamping, engraving, and silk-screen printing. These techniques can add luxurious details to your bottle, making it a stunning addition to your fragrance collection.

Q: How can hot stamping enhance the design of a perfume bottle?

A: Hot stamping is a decorative technique that involves applying metallic or colored foils to the surface of the bottle. This can add a high-end, luxurious finish to your cologne bottle or eau de parfum, making it stand out in your perfume line.

Q: What should I consider when choosing a cap for my custom perfume bottle?

A: When selecting a cap for your custom perfume bottle, consider the overall design and functionality. The cap should complement the bottle’s style and ensure a secure fit to preserve the fragrance. High-quality materials and unique designs can add to the luxurious feel of your personalized perfume.

Q: What is the importance of the pump in a perfume bottle design?

A: The pump is crucial for the functionality of a perfume bottle, as it allows for the easy application of the fragrance. A well-designed pump ensures a fine mist and consistent distribution of the scent. It’s an essential component for both aesthetic and practical reasons in high-end perfume designs.

Q: Why is it beneficial to work with an in-house design team for perfume bottles?

A: Collaborating with an in-house design team can streamline the process of creating a custom perfume bottle. These teams typically have extensive experience and can offer personalized advice, ensuring that the final product aligns with your vision and maintains the integrity of your fragrance collection.

Q: How can I make my perfume line stand out with unique bottle designs?

A: To make your perfume line stand out, consider using niche designs that reflect the essence of your fragrances. Unique shapes, innovative materials, and personalized touches like hot stamping can create a signature look that distinguishes your line from others on the market.

Q: What role does a sample play in designing a custom perfume bottle?

A: Samples are vital in the design process as they allow you to review and test the bottle design before full production. This ensures that any adjustments can be made to meet your specifications and that the final product aligns perfectly with your vision for your perfume line.

Q: How does the choice of materials impact the design of perfume glass bottles?

A: The choice of materials significantly impacts the aesthetics and durability of perfume glass bottles. High-quality materials can enhance the luxurious feel and ensure the longevity of the bottle, while also offering a range of customization options to suit the design of your niche fragrances.

Q: What is the difference between eau de parfum and other fragrance types in terms of bottle design?

A: Eau de parfum generally requires a more robust and airtight bottle design to preserve its concentrated formula. This often results in more elaborate and decorative bottles that reflect the richness of the fragrance, distinguishing it from lighter scent types like eau de toilette.