Creating a perfume bottle is a complex, fascinating subject blending art, engineering, and sustainability to finally give some of the world’s famous fragrances their beautiful containers. The whole manufacturing process-from the raw grains of sand forming the basis of the glass to the finished product, polished and gleaming, on display in stores-is filled with stages, each to ensure both aesthetic and functional properties. This blog will take a dive into the captivating world of perfume bottle manufacturing, unveiling the exact methods, latest technologies, and the creative designs that bring to life these iconic vessels. Be it the curious consumer, a fragrance aficionado, or just anyone interested in the seamless interplay of science and art, this journey will give you a behind-the-scenes perspective into the art of craft that goes into every perfume bottle.

Understanding the Manufacturing Process of Perfume Bottles

The stages involved in making perfume bottles are numerous, ensuring both functionality and beauty. During the design stage, various creative ideas are transformed into detailed drawings with consideration of different factors such as the volume, forms and structure of the bottle. In the second stage, raw materials such as glass or plastic are cut to size and machined with the help of very precise tools to the desired shape. The shaped bottles are then placed in molds and cooled. Later they are polished and checked for quality. Decorations may include etched designs, paint colours or metallic institutions applied to the bottle’s surface to bring out beauty. Lastly, the bottles, caps, and sprayers are fitted to the bottles ready for the filling process. All these steps are to be properly executed in order to ensure that all specifications regarding the quality and the fairness of the product are adhered to.

Overview of the Perfume Bottle Manufacturing Process

To comprehend how perfume bottles are made, one needs to look into glass making process. For that purpose, elements namely sand, soda and lime are heated in a furnace to cause formation of glass. After this, the glass is placed inside a mold with/without pressure so as to make it/them into a bottle. The formed bottle/bottles is/are then checked for any defects through a process of cooling. They may be decorated with color, textures or even engravings to suit the needs of the buyer. In conclusion mini-caps and sprayers are assembled into the bottles while leaving space to fill in perfume later on.

Key Stages in Bottle Production

- Design and Concept Development

The production process begins with creative teams in the design phase, where concept identities are translated into bottle designs-from initial sketches to 3D modeling and material selection-to produce a bottle that is visually appealing and functional. - Material Selection and Preparation

A selection must be made from the different types of quality material available today, such as glass and plastics, depending on the design specifications. The materials are then carried through process operations to be melted or shaped with utmost care for safety and aesthetics. - Shaping and Forming

The bottling step uses advanced molding techniques-clean blow molding for glass bottles or injection molding for plastics-to shape the bottle and ensure accurate proportions, uniformity, and structural integrity. - Cooling and Inspection

The bottles, once shaped, are then cooled by rapid means. That rapid cooling should target solidification of the material and be supported by stringent quality control measures for visual and mechanical inspection to detect any inconsistencies or defects. - Decoration and Finishing

This step is carried out for beautifying the bottle, which includes coating, engraving brand logos, coloring, or texturing. Often, either a screen printing or hot stamping method is employed at this time. - Assembly and Packaging

During the post-decoration stage, various components such as pistons, atomizers, and sprays may be attached. After this, the bottles are securely packed for transport to the filling station.

Each stage in perfume bottle production is designed to make sure that the final product is aesthetically pleasing and functional and resonates with the elegance and grandeur of the fragrance it holds.

The Importance of Packaging in the Perfume Industry

The art and science of packaging are integral to the manufacture and sale of perfumes, contrary to what most may think. In fact, packaging is more than just how perfume bottles are made and how aromas are contained. Its beautiful package assures the consumer that it is of good quality and therefore the product is safe to be kept and transported without any damage to it. The Golden Arches or McDonald’s logo, which serves as a good example of the packaging, is in fact more than just decoration. The architecture, the colors and the materials of the product can trigger a certain feeling, tell the history of the smell or even make one feel elegant and classy. Without doubt, good packaging adds value to a product and at the same time promotes the company positively.

Materials Used in Perfume Bottles

How perfume bottles are made is a question that almost all niches have since these containers determine customers’ first impression of a perfume. Glass is the most commonly used material because of its preserving and clear luxury characteristics. Light plastic and clear glasses can also be used to create bottles, and tutu which would not easily break can be made of high-quality plastic. Finishes can also be made of aluminum or even in some cases stainless steel or any other metal elements, as well as clear or protective car- based finishing. Additionally certain ceramic or wooden components are sometimes used in some designs for artistic effects.

Types of Materials and Their Properties

Perfume bottles are commonly made of materials such as glass, plastic, metal, ceramic, and wood, each chosen for their specific properties and aesthetic appeal.

| Material | Properties | Use | Features |

|---|---|---|---|

| Glass | Transparent, durable | Preservation, luxury | Fragile |

| Plastic | Lightweight, shatter-resistant | Practical, portable | Affordable |

| Metal | Sturdy, corrosion-resistant | Caps, accents | Durable |

| Ceramic | Unique texture, non-porous | Decorative elements | Elegant |

| Wood | Natural, textured | Aesthetic accents | Eco-friendly |

The Role of Glass in Perfume Bottle Manufacturing

In understanding how perfume bottles are made, it can be argued that functional as well as aesthetic factors make glass very important. First, there is the obvious feature of glass, which is that it is translucent. In this way, all the bright colors and even the clear perfume within the bottle can be seen elegantly in that glass bottle without any difficulties. Next, there is the fact that glass does not let the perfume penetrate through nor reacts with it, hence it can avoid deterioration over long periods of time. With glass there are also much more sophisticated manufacturing methods than was possible some decades ago which incorporate creative shapes, designs that are imprinted, completion finishes, and embellishments. All of this makes glass capable of remaining as one of the most preferred materials used in designing perfume bottles, combining the history and the tradition with modern approaches.

Alternative Materials in Cosmetic Packaging

Growing interest in environmentally-friendly packaging has led to a growth of usage of sustainable and innovative materials in the cosmetic packaging industry. Consumers have long enjoyed the use of lightweight and strong plastic containers such as PET, and HDPE which can be refilled and more importantly recycled . A very attractive and functional solution that keeps the use of Plastic to the minimal by utilizing all provided metal alternatives including aluminum is metal packaging. Paperboard is another environmentally friendly solution that is now gaining popularity as a secondary packaging material. Such solutions are not only functional and attractive, but they adjust to the consumer who wants to be mindful of the environment while making purchases.

Design and Aesthetics of Perfume Bottles

How perfume bottles are made is a crucial topic. Perfume bottles are designed with intent and sincerity. Form, shade, type of material and every single minute detail is taken into considertaion by designers to come up with a story that can work for a certain brand and its target market. When it comes to appreciation of the design of a bottle, the basic use of the bottle is overshadowed by the aesthetics of atheistic proportions.

Understanding Different Bottle Designs

There are many styles for different perfume bottles, which may take from traditional classic or cultural aesthetics to luxury packaging. One extreme is perfect minimalism, using only straight lines and monotonic colors popular among younger generation due to their reluctance to embrace clutter and fake opulence. On another note, flamboyant spheres cut in complicated knots with flowers and jewels carved from recesses and embossments go to the category of realism. With the emphasis on green marketing though, one would find refillable or recyclable bottles in abundance. “How perfume bottles are made” is perhaps as much a coverage of the things that will be used in the market as of which parts of the brand and fragrance statement come to play in most cases.

Luxury Perfume Bottle Design Trends

- 1

Minimalist Aesthetics

Modern luxury perfume bottles feature clean lines and simple shapes for the consumers who value elegance and understated beauty. - 2

Sustainable Materials

Brands increasingly opt for recyclable and environmentally friendly options—including glass packaging and biodegradable packaging—to keep in step with environmental crises and attract green customers. - 3

Personalization

Personalized bottle engraving is now in vogue, where consumers can add a first name, last name, or monogram-like engraving that lends a touch of uniqueness and intimacy. - 4

Artistic Inspirations

Most perfume bottles embody art themselves; a few are made with beautiful sculpture and imaginative forms so as to connote exclusiveness and prestige. - 5

Refillable Designs

Refillable bottles are becoming more and more popular, offering a combination of refinement and sustainability where the consumer can enjoy aesthetics while cutting on waste over time.

This very much witnesses an evolving industry balancing aesthetics, innovation, and environmental consciousness to respond to the needs of the modern consumer.

The Evolution of Perfume Bottles Over Time

The designs of scent bottles, from a simple primal form to a complex molded form denote the social and cultural transformation of the society. For instance, as far back as the early civilizations like the Egyptians and Greeks are concerned, their fragrant oils were basically stored in earthen or glass like containers. Such vessels were often simple, and their purpose was purely to contain the scent.

By the time of Renaissance, perfume bottles were no longer just containers for perfume but also objects of artistic craftsmanship of that period with elaborate forms. Glass mixers and glass artisans manufactured sophisticated containers filled with filigree, gilding and semiprecious stones making the containers as enticing as the contents. The era of the 19th century was a time when industrialization appeared and as such, how perfume bottles are made changed to permit mass production with traditional designs.

Perfume brands became partners with fashion designers in the 1900s, and such cooperation gave the world luxurious perfume bottles which could at times reflect the fashion trend, art direction or even the particular characteristics of the scent. With new materials such as crystal and complex decorative plastics, the creativity in design was always innovative and unforgettable.

Nowadays, bottle design incorporates both aesthetics and practicality while heading towards ecological sustainability. Modern businesses practice selling the specific perfumes and refills, bottles more simple in design, or with green materials are also available which can also attract affluent environmentalists. That movement illustrates the way how perfume bottles are made, once simple containers, masks are now becoming works of art.

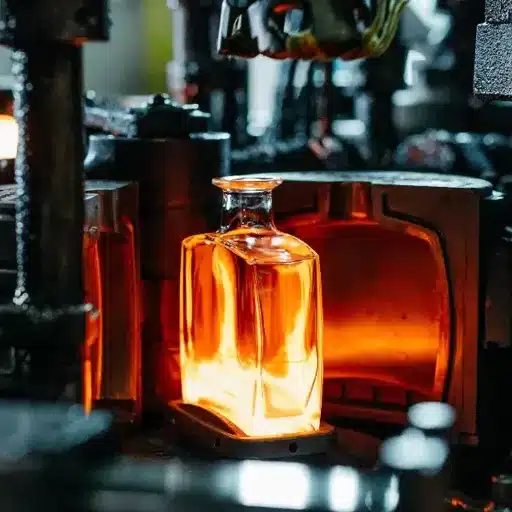

The Manufacturing Process of Glass Perfume Bottles

To understand how perfume bottles are made, it is essential to know about the individual stages involved. An important point to note is that silica sand, soda ash, and limestone, the main silicate forming materials, must first be melted down to produce glass. Since glass allows molds to be placed around it, there is typically a blowing and pressing process for molding the glass into a perfume bottle’s shape. Following this molding process, the formed bottles, are brought to the correct temperature and let cool gradually to release any inner stress. Also, once completed, the bottles will be processed on the surface, polished, and decorated in various ways such as etching with engravings or placing images. Finally, as the ultimate goal is to fill the bottles with perfume, quality assurance tests the product to ensure it is of good quality and safe to use.

Step-by-Step Guide to Bottle Production

- Design and Concept

Begin with the conception and rendering of a very detailed mockup of the perfume bottle concerning aesthetics, practicality, and branding. - Material Selection

Choose the appropriate type of glass or alternative material that would suit the intended design and functionality. - Melting the Glass

In a first step, raw materials consisting of silica sand, soda ash, and limestone are heated in the furnace to produce a molten glass. - Shaping of the Bottle

Blow, press, or mold the glass into the free-form shape of the bottles. - Annealing Process

The bottles are slowly cooled in an annealing oven to relieve stress in the glass and allow for greater durability. - Surface Treatment and Finishing

Treatment is applied to strengthen the glass and ensure it is smooth and polished for a perfect aesthetic. - Decoration and Branding

Engraving, staining, or decals to give the finished bottle its unique artistic character that corresponds with its brand language. - Quality Control

Inspect the bottles to ascertain that all functional and cosmetic standards are met in terms of durability, shape consistency, and correct design. - Filling Preparation

Sterilize and prepare the bottles for the perfume filling. - Filling and Sealing

Fill bottles with perfume and seal them with no leaks or contamination. - Final Inspection

Carry out an ultimate quality control to ascertain that the finished perfume bottles are perfect and ready for packaging. - Packaging and Distribution

The bottles will be packed attractively and safely for shipping and delivered to their destinations.

Techniques in Glass Production for Perfume Bottles

In the manufacturing of glass perfume bottles, there is the blending of traditional processes along with modern techniques. This combined approach guarantees durability, looks, and functionality. Some main glass production methods are:

- Glass Blow Molding – In this process, molten glass is shaped by inflating it into a mold with pressurized air. It can be used for the most intricate designs, which are usually required for luxury perfume bottles.

- Press-and-Blow – For smaller bottles with simple shapes, first, a plunger presses the glass into shape. Then air is forced into the cavity to complete the final dimensions.

- Hand-blowing – In this very traditional method, a skilled craftsman manually blows molten glass into shapes, allowing for exquisite detailing and uniqueness in the making of high-end or custom bottles.

- Tempering of Glass – To improve durability, a process of tempering is done by rapidly cooling glass when it remains heated, thereby increasing resistance against scratches and breakage.

- Surface Treatments – Whatever the treatment, frosting, coloring, or metallic finishes must have a strong visual effect on that perfume bottle. Designer frequently choose acid etching or sandblasting as methods that make for their decorative finishes.

- Sustainable Practices – Nowadays, more and more manufacturers are using recycled glass and environmentally friendly materials in bottle production to lessen environmental impact while retaining the quality.

These, along with great precision and artistry, allow the perfume bottle not only to be functional packaging but to become an elegant design piece as well.

Quality Control in Bottle Manufacturing

Ensuring durability, precision, and beauty of perfume bottles is one of the most stringent aspects in how perfume bottles are made. Ensuing this objective, the manufacturing process further includes numerous phases of quality control like material check for faults, weight distribution and thickness. Eyes exercise is also made in order to notice flaws, if any exist: bubbles, marks or rough surfaces. Functional tests check whether the bottle is hermetically sealed or, if it is to be a spray type whether it is functional. All these robust techniques provide assurance to the manufacturers that no bottle produced is of substandard quality and every bottle serves its purpose and looks good.

Finishing Touches and Packaging

Eventually the bottles that pass the preliminary inspection stage are given the final finish such as polishing, painting or engraving in order to make the bottles look prettier. All through the process from placing fitments upon the trays to application of final labeling it is seen that the elegance of presentation is maintained. At last, the bottles are shattered wrapped ,commonly in artistically designed boxes, to preserve their qualitic and appeal features in transit and when on display.

Labeling and Branding of Perfume Bottles

The work of labeling and labeling-ready satisfying the market’s which involves perspective consists of a label and a logo which, without them the perfumer’s brand will be the with the customers. This label in case of perfumes has the name of perfume and the customers brand explores some additional info such as fragrance type and quantity of perfume another way it designers create a stylish font decoration answering the brand. These are fused structures sensitive to color and form unique shape of the stylists so social institutions assist in making their marketing strategy. All this is not just the important information put inside but also is amarketing tool with all longest make into market and an attachment to customers of a bottle.

Eco-Friendly Packaging Solutions in the Industry

The perfume industry is turning towards environmentally sustainable packaging to meet the consumer’s high expectations for sustainability. For the most part, active brands now seek to use biodegradable materials, recyclable glass bottles, and refillable packaging wherever possible to minimize harms to the environment. Many also minimize the use of plastic by primarily using bamboo or aluminum in the making of their caps or covering. On hello insight as to increased use of innovative products more and more companies are gradually looking at adoption of technological process – including but not limited to those which utilise known recycling or even carbon neutral processes. With regard to these practices, the perfume business does not only focus on minimizing wastes, but also a lot of can be achieved within the framework of a circular economy – thereby providing the possibility for clients to buy luxury goods with a lower environmental impact.

Final Steps in the Perfume Bottle Manufacturing Process

The perfume bottles production process’ last stages involve an exquisite balance between art and supervising the quality. Once the bottles are designed and assembled, there is a need for proper cleaning, such that all impurities are removed. This activity is then coupled with products’ refill that calls for the use of machinery for the correct perfume dosing without any losses through spillages. Post-filling, the bottles are capped or have pumps attached depending on the configuration of the bottle.

Then come the steps of labelling and packaging. High standard labels are placed on the bottles to match the status of the brand and emptied bottles are packed into safe containers. At last after production, the products are subjected to stringent level of control in consideration of the appearance or the function or both, before being shipped out to the consumers. This description shows how perfume bottles are made using art and technology.

Reference Sources

- •

How are glass perfume bottles made? – Knowledge

This source explains the two main processes used in glass perfume bottle production: blow molding and compression blow molding. - •

Manufacturing process of glass perfume bottles: the art …

This article dives into the detailed manufacturing process, covering raw material ratios, molding technology, and environmental considerations. - •

How Do Perfume Bottle Manufacturers Craft the Perfect …

This source discusses the steps involved in crafting glass perfume bottles, including material melting, mold shaping, and final production.

Frequently Asked Questions (FAQs)

How do they manufacture perfume bottles by means of modern techniques?

Perfume bottles are made with a mixture of traditional craftsmanship and modern techniques. The production process begins ideally with the best glass, and it is melted and shaped either by blowing or pressing. This way, many shapes and designs can be fashioned to suit the ever-changing tastes of the consumer.

What materials go into producing perfume bottles?

The more usual materials for perfume bottles are high-grade glass, plastics, and sometimes ceramic materials. Glass is used on account of its beauty and its ability to keep the perfume in good condition: whereas plastics are more lightweight and cheaper for some brands.

What kind of different perfume bottles are there?

Perfume bottles vary from plain glass vessels to highly ornamental, luxury perfume bottles. Common types include spray bottles, roll-on bottles, and splash bottles; design and manufacture of the bottles are done purposely with the consumer’s comfort in mind and reflecting the brand identity.

What is implied in the design of a perfume bottle?

Bottle design has a marketing function and affects consumer behavior. Attention-grabbing bottles are able to communicate with the customer and advertise the brand at the same time. At the same time, the bottle should be handiwork that fits the product.

What processes are used to make perfume bottles?

Most of the common techniques prominent in perfume bottle manufacturing are glass blowing, molding, and pressing. These techniques allow artisans to fabricate with ultrapurity glass into any conceivable shape, thus proliferating an array with which brands can differentiate themselves in the market.

What sustains the act of perfume bottle production in the present day?

These days, sustainability finds a great deal of impetus in perfume bottle production as many companies look into environmentally friendly materials and processes. One way is recycling glass and others concerning minimizing waste generation at the manufacturing level-abiding consumer call for greener products.