OEM (Original Equipment Manufacturer), the world of perfume bottle manufacturing is equally complex and filled with opportunity, allowing businesses to bring their custom, high-quality fragrance packaging to market. Familiarity with contract production process problems is the only way to achieve productivity, cost savings, and brand fit. This guide will provide you with the complete OEM perfume bottle manufacturing process, from concept to production, quality control, and beyond. Suppose you are an established brand looking for unique, creative packaging, or a newcomer still figuring out how to get your products manufactured. In that case, this article will provide the information you need to create trendsetting products that are must-haves in a highly competitive market. Follow us through the manufacturing process, learn about the main success factors, and explore the different performance modes and ways to achieve the objective.

Understanding OEM Perfume Bottles

OEM (Original Equipment Manufacturer) perfume bottles are containers specially produced for a particular brand or customer. These containers are made with the brand’s guidelines in mind, using unusual shapes, materials, and finishing touches that align with the brand’s values. The OEM procedure is a tool for companies to get stand-out packaging that sets their products apart in a competitive market. In general, manufacturers handle all stages of production, from the creation of the design and sourcing of materials to manufacturing and quality control, ensuring that the final product meets the given specifications and is of high quality. The market for these bottles is very competitive, and well-known perfume brands and new businesses use them as part of their brand-building strategy to achieve the exact brand positioning and professional look.

What are OEM Perfume Bottles?

OEM (Original Equipment Manufacturer) perfume bottles are manufactured by a single company with expertise in crafting custom packaging for perfume brands. The purpose of the bottle is to express the vision and brand idea through a unique bottle design, finish, and shape. The manufacturing process is based on high technology and precise engineering to ensure the bottles will fully comply with the quality and industry standards. The use of OEM perfume bottles is a hit for brand marketing leaders, as it makes them stand out by offering tailored packaging that end-users can easily spot. The market gives it a thumbs up and, consequently, it aligns with the brand’s fashion. Furthermore, the OEM solutions are widely known for being made with environmentally friendly materials and featuring cutting-edge designs, reflecting an attitude towards the environmentally friendly packaging trend in the fragrance market that is becoming increasingly binding. The bottles themselves not only fulfill their practical role but are also an essential part of the product, making it more valuable and gaining a higher market position in consumers’ view.

Benefits of Using OEM Perfume Bottles

1

Customization to Meet Brand Identity

OEM perfume bottles are highly customizable, which motivates the brand to fine-tune the design, shape, and appearance to match their own identity exactly. The report states that when a product’s packaging reflects its preferences and aligns with the brand’s image, 84% of clients are more inclined to buy.

2

Enhanced Product Differentiation

Custom-made OEM bottles, one of the upsides, greatly helped differentiate the designs, getting the brand’s products out of the crowd. It not only won the users’ trust but also made them loyal to the brand. According to a recent study, 65% of consumers always make purchasing decisions for innovative packaged goods.

3

Sustainable and Eco-Friendly Options

Given the growing popularity of eco-friendly products, many original equipment manufacturers today use recyclable or compostable materials in their packaging solutions. The use of personally designed containers with a green tag drastically reduces carbon emissions, which is a big draw for the market full of environmental protection enthusiasts. Preconditions that push environmentally conscious consumers towards such a market include the fast-approaching numbers that will bring the global eco-friendly packaging market to a whopping 413 billion dollars by the year 2027.

4

Cost Efficiency in Large-Scale Production

The brand’s partnership with the OEM manufacturer helps achieve large-scale production. As far as the customized fragrance containers are concerned, mass production helps reduce unit prices, which, in turn, makes the whole process much more economical than manufacturing in small numbers or importing ordinary bottles.

5

Integration of Innovative Features

OEM solutions typically offer the option to integrate innovative packaging, spray mechanisms, or refillable designs. The presence of these advanced features can result in the user getting a much better product. One example is that innovative packaging in the cosmetic industry is expected to grow at a 9.5% CAGR between 2023 and 2030.

6

Consistency and Quality Assurance

OEM manufacturers guarantee the use of high-quality production processes that adhere to industry standards. Because of this, as changes are carried out from manufacturing to market, a brand’s standing in the eyes of consumers remains the same, and the company can provide customers with packaging of the same high, premium quality every time a product is made.

Key Features of OEM Perfume Bottles

Customizable Designs

Original Equipment Manufacturers (OEMs) perfume bottles are now available in so many design options that well-established names in the luxury industry can create truly unique, high-end packaging that strongly aligns with their trademark and is very identifiable. This flexibility is not limited to size and shape but also to the material used and to design elements such as engraving, embossing, and finishing coating.

High-Quality Materials

The use of high-quality materials such as glass, aluminum, and premium plastics during production not only results in a longer-lasting product but also adds appeal. For example, it is little known, but borosilicate glass was already famous for its outstanding resistance to thermal shock and the stability it provides.

Advanced Production Techniques

Thanks to the use of the latest production methods, such as injection molding, blow molding, and precise CNC machining by OEM manufacturers, their design details are produced with very high precision, while material waste is minimal.

Innovative Dispensing Mechanisms

The perfume bottles and their functionality, as well as user-friendliness, are improved by advanced dispensing solutions, including locking pumps, fine-mist sprayers, and airtight closures.

Eco-Friendly Options

Many OEM companies are adopting sustainable practices by offering customers eco-friendly packaging, including recyclable materials, biodegradable coatings, and refillable bottle designs, all of which align with the growing demand for sustainability in the fragrance industry.

Compliance with Industry Standards

OEM perfume bottles are produced in accordance with industry standards such as ISO and ASTM to ensure they are safe, reliable, and of high quality. This is vital for business, as it will improve customer loyalty and thus serve as a branding asset.

Manufacturing Processes for OEM Perfume Bottles

-

1

Design and Prototyping

To kick things off, a thorough design that details the parts, shapes, and functions needs to be created. Then, models that are often developed using cutting-edge 3D modeling and printing can be used to check whether the product looks good and performs well.

-

2

Material Selection

Glass, aluminum, or certain premium-quality plastics are used, determined by the need for durability, appearance, and environmental impact. It’s also essential that the materials meet the industry’s minimum safety requirements and that we understand their compatibility with the fragrance formulations.

-

3

Molding and Shaping

Among the methods, glassblowing, plastic injection molding, and extrusion are the most common techniques used to shape the bottle. It is essential to maintain precision at this step to maintain product uniformity and reduce defects.

-

4

Surface Treatment and Coating

The bottle will also undergo surface finishing, including polishing, frosting, and specialized coatings, to make it more attractive and functional. Different types of coating, such as scratch or UV, may be added for protection and appeal.

-

5

Decoration and Customization

The final product is also endowed with branding elements like logos, text, or intricate patterns by being incorporated, for instance, through screen printing, hot stamping, or laser engraving. Doing so adds the company’s quality and personal touch to the product about to be made.

-

6

Quality Control and Inspection

Rigorous quality checks are conducted at various points to identify and correct potential defects. Testing is carried out to ensure that the bottles’ safety, durability, and design requirements are met before they are allowed into mass production.

Material Selection: Glass vs. Crystal

| Parameter | Glass | Crystal |

|---|---|---|

| Composition | Made from silica, soda, and lime | Contains lead or lead-free compounds |

| Durability | High resistance to scratches | Relatively softer and delicate |

| Transparency | Less refractive, standard clarity | High refractive, brilliant clarity |

| Weight | Lightweight | Heavier due to lead content |

| Sound Quality | Dull when tapped | Produces a resonant “ring” |

| Cost | Generally affordable | Higher manufacturing cost |

| Production Flexibility | Easier to mold and shape | Requires precision in craftsmanship |

| Applications | Everyday use, practical containers | Luxury items, decorative bottles |

| Environmental Impact | Easier to recycle | Recycling is more complex |

| Thermal Resistance | Moderate heat resistance | Can withstand higher temperatures |

Quality Control in OEM Production

One of the most critical processes in Original Equipment Manufacturer (OEM) production is quality control, which ensures products meet defined standards and specifications before they are delivered to the final consumer. It is a very detailed process, staged throughout the production cycle, from material sourcing to final inspections. Techniques such as statistical process control (SPC), Six Sigma methodologies, and real-time monitoring systems are among the most popular for identifying and eliminating defect cherry-picking at the initial stage of the production line.

Developments in quality assurance technology have enabled the simultaneous integration of machine learning and AI-powered analytics. Consequently, this has opened the way for the use of Predictive Quality Maintenance (PQM) and Automatic Fault Detection. Plant data from high-precision sensors integrates into software dedicated to the continuous monitoring of all production metrics, ensuring components meet the required high quality and are accurate to a few micrometers in the automotive and aerospace manufacturing industries. Moreover, neither the OEMs nor the codes of conduct of the ISO 9001 standard can diminish the importance of certification since it’s both the operators’ and the industry’s reputation.

The policy of tight quality control not only helps reduce the cost of rework and warranty claims but also helps mitigate the weakening of customer trust, which is so essential to the business in the face of stiff regional and global market challenges.

Customization Options for OEM Perfume Bottles

OEM perfume bottles are undeniably the best choice for customization, as they can meet a wide range of brand-specific requirements. Key areas of customization include:

-

Bottle Design

When it comes to flask design, you will not be stuck with one, since shape, size, and material can all be tailored to the brand’s aesthetic. Of course, you can choose among the available eco-friendly materials.

-

Color and Finish

The entire process of matching the color and finish to the chosen Pantone code will ensure a color that accurately represents the brand. The options offered are excellent, including transparent, frosted, metallic, and gradient finishes.

-

Cap and Spray Nozzle

The bottles can be made by 3D printing designs of your choice in any shape and material, while the spray nozzles can have any color and appearance; thereby, the dispensing volume and design can show unique, optimal features.

-

Decoration Techniques

Decorating, such as laser filing or hot stamping, can be employed to bring out colors and make things look more appealing and more representative of the brand.

-

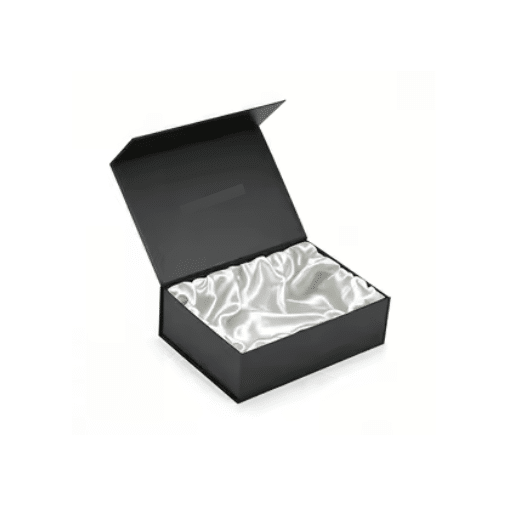

Packaging and Labels

The bottle itself is not the only part of the product to sell but also the packaging and the design of it as well as the printing of the labels; this is how you get the complete product the way you want it to reflect your brand’s personality, and it provides room for a variety of choices for the outer vacuum-sealed packaging to be eco-friendly or luxury-like materials.

By exploiting these customization opportunities, brands can design standout fragrance bottles that attract customers while also maintaining practicality and brand image.

Designing Your Customizable Perfume Bottle

It is crucial to take into account the three aspects —function, beauty, and the intended market segment —when developing a customized perfume bottle, so that the end product is in tune with the latest market and consumer demands. The process should begin by choosing a bottle silhouette, masses that align with the scent category, and the kind of users you are targeting. For example, a contemporary, futuristic image can be seen in bottles with a very sharp cut. In contrast, other bottles of a previous form are more likely to convey an expensive look.

Choosing the right material is a critical factor as well. Although glass has always been a preferred material for its longevity and scent retention, more sustainable options like recycled glass or disposable materials are increasingly popular due to the eco-friendly consumer landscape. Furthermore, the design step includes the dispensing mechanisms, and their functionality is also considered. These can range from atomizers, rollerballs, to droppers, each of which is specific to the viscosity of your fragrance solution.

Moreover, the product’s manufacturing can contribute to the user’s overall perception of the brand. There is a possibility of making a brand stand out even more by foiling it with a metallic color, for example, using UV coatings to achieve a luxurious finish, or by adding intricate engravings. The former will attract high-end markets through the tactile and visual cues the materials convey, and the latter is a way to make a brand stand out or draw attention to it. Typically, the more complex the design, the less scalable and more expensive it is in a low-end market.

Comprehension of regulations in the packaging and material field is vital. For example, the certification of each part to international safety and environmental standards is a significant step in the manufacturing cycle. You will be able to observe and adjust everything, reducing mistakes and improving production flow by using 3D modeling tools for prototyping during the design phase. You can easily convince customers that you are the right choice for them and that you offer the most up-to-date, beautiful products they want.

Labeling and Branding Opportunities

Labeling and branding, intrinsic to perfume personalization, offer a plethora of opportunities to effectively communicate a brand’s identity while complying with the law. The modern use of various printing technologies, such as UV printing and laser cutting, ensures the application of a brand in a precise and durable way, while also making it easy to render intricate designs and even important product information. Additionally, the use of recyclable and sustainable materials is becoming popular among label manufacturers who want to be seen as environmentally friendly and, at the same time, attract the eco-conscious consumer market. The use of technologies like QR codes or NFC tags on labels opens endless possibilities for a brand to connect with the digital world, as they allow users to access detailed product information and, through an app, even participate in a virtual event. Digital receipts are meanwhile being issued as proof of the exchange of goods, while an attempt is being made to eliminate paper by providing product documents on the company’s servers. The selection of brand dimensions, color theme, paper texture, and label lamination all affect a product’s graphical appeal and memorability.

Market Trends in the OEM Perfume Bottle Industry

The OEM perfume bottle industry is significantly influenced by sustainability, innovation, and customization as new market values. The research strongly shows that the supply of eco-friendly products, particularly those made with recycled glass and biodegradable components, is on the rise, and companies are taking eco-consciousness very seriously to capture customers who share the same values. Additionally, the development of 3D printing and similar methods has not only changed the manufacturing world but also affirmed that designers’ inhibitions are limitless; consequently, customers are more satisfied with customized products and services. Personalization remains a significant factor, and you can see brands targeting very niche markets by offering custom packaging solutions. Besides, the cost of shipping and the environmental impact of carbon emissions have to be taken into account, so the trend is towards bottle designs that are light and easy to carry, which also minimize shipping costs and carbon emissions.

Current Trends in Fragrance Packaging

A remarkable trend in the perfume packaging field is the use of “green” materials that can be recycled. Due to the high priority given to the environment and the use of materials like bio-based polymers, recycled glass, and the like, not only the brands but also the suppliers are playing their part in preserving the environment, so that the Earth emits only a modest amount of CO2. It is pretty standard, for example, to find glass containers made from 100% recycled post-consumer waste. Such products are still tough and long-lasting while meeting ecological demands. Moreover, the way is being paved for the use of refillable packages, which are in high demand nowadays as more brands open refill stations or create subscription plans, ultimately reducing a significant portion of the waste from single-use packaging. This move corresponds to the two-pronged approach reflected in the market appeal and the persistently strict laws meant to achieve the gradual realization of environmental goals.

A rise in the production of fragrance packaging that emphasizes multisensory experiences has also been identified as a significant factor. Fusing touch sensations with visual and olfactory appeal, brands are bringing ideas to market in the form of intriguing designs through textured surfaces, metallic finishes, and innovative closures. Furthermore, these little touches not only give the product a luxurious feel but also help create its story. Augmented reality (AR) is also employed in the same field to provide customers with digital interactions they can enjoy and to enable two-way communication between the brand and its products. This union of technology with design also offers a brand-new unboxing experience, giving a special touch that is felt and remembered.

Future Projections for the OEM Market

The Original Equipment Manufacturer (OEM) market is expected to grow gradually, driven by advances in automation and sustainability, as well as the rising demand for personalized products. Predictions from industry experts show that manufacturing processes worldwide are moving towards digital manufacturing ever more, with the creation of communication channels via the IoT and AI-powered systems streamlining production processes and logistics. These are performance improvements expected to closely follow the cost reductions and thus place the OEMs in a better competitive position.

Furthermore, green manufacturing is becoming a significant area of concern. The implementation of renewable energy sources and the use of recyclable materials are the most sought-after options as environmental legislation becomes stricter worldwide. It is expected that this will lead to innovations in both products and logistics, in a way that enables the organization to comply and, at the same time, be socially responsible.

The need for specialized solutions tailored to end users’ needs is increasing, especially in sectors such as automotive, electronics, and industrial equipment. The move towards hyper-personalization mirrors changes in consumer tastes and has led OEMs to invest heavily in modular design and new engineering.

According to market research, the Asia-Pacific region is seen as a good place to grow business, with an exploding manufacturing sector, state aid, and increasing investments in technology. The Asian-Pacific market is also seeing more and more OEMs collaborate with Technology Providers, which is a clear sign of the market’s continuous evolution and therefore a scenario that is innovation- and adaptability-friendly.

Choosing the Right OEM Perfume Bottle Supplier

When you want to choose a manufacturer who supplies perfume bottles directly to the customer, there are a few essential factors that should be taken into account so that the partnership can be a success:

Quality Standards

One of the main things is to be sure that the manufacturer has in place the highest standards of quality assurance. Seek out ISO 9001 certifications or similar certifications as strong proof of their consistent, high-quality material production.

Customization Capabilities

Make sure the provider guarantees these design and material options while also accommodating not only your brand’s appearance but also its efficiency requirements. They must be competent enough to come up with the perfect, ingenious solution.

Production Capacity and Lead Times

Estimate whether the supplier can meet your production demands without any glitches. It is critical to maintain clear communication about the time the product will be delivered and the ability to support the production your company needs, especially during seasons when manufacturers are at full capacity.

Cost Competitiveness

The lowest price does not always mean the lowest total if the quality or service is good. You may also want to choose one of those hosting providers that offer scalability along with the hosting packages.

Sustainability Practices

Carefully go through every step of the supplier’s sustainability practices; for instance, using recyclable materials or eco-friendly production methods is a plus for the brand. Stay attuned to global sustainability trends by aligning your brand’s image.

Reputation and References

Review the supplier’s reputation in the industry by reading reviews, studying case studies, or contacting the company’s distributors. A successful history is the best indicator of the distributor’s reliability.

Evaluating Potential Suppliers

When evaluating potential suppliers, it is critical to gather data from multiple sources to ensure the most complete evaluation. Key performance indicators (KPIs) such as on-time delivery, defects, and order accuracy, along with any performance benchmarks, are the metrics to use for objective measures. Besides, a company that has implemented technology solutions is very likely the one you are looking for. e.g., a company that uses a very advanced logistics system and/or has an automated production line.

Market performance is a vital aspect that requires continuous analysis. Companies that understand the industry and correctly identify consumers’ exact demands and requirements perform better and are even called ‘partners’. In addition to reviewing these reports or studies related to the given industry, differences in historical data across suppliers should be carefully assessed. Another way to look at it is to determine the industry’s advancements, trends, and market acceptance to position the supplier’s products accordingly. Actual professional efficiency in product development and solutions, a water-tight supply chain, and quality management are among the most important factors to consider when making the final decision.

Factors to Consider When Partnering with a Manufacturer

Technological know-how is the ultimate element when choosing a manufacturing company. The use of production methods such as automation, robotics, and precision engineering demonstrates a manufacturer’s ability to do one thing – produce lots of excellent products in the same way. Moreover, given their focus on research and development, and the way they implement the 4.0 revolution, this can be a perfect way to understand their ability to innovate and be efficient. Companies that equip their production with cutting-edge technologies are their own agents, achieving higher accuracy, less downtime, and the narrowest distance between models, which are key elements for maintaining the same level of competitiveness on the global market. Beyond that, understanding their technological base not only indicates if that is the way your company wants to go in terms of technology, but also validates their cohesiveness in addressing new industry demands.

Reference Sources

Why Choose OEM Perfume Packaging? – Abely

Summary: This article explains the benefits of OEM perfume packaging, emphasizing its role in enhancing brand image, saving costs, and accelerating time-to-market.

Perfume Bottle Design: The Crucial Element in Branding Fragrances – Jarsking

Summary: This article delves into the significance of perfume bottle design in branding. It explains how OEM services help brands create unique designs that resonate with their target audience.

Frequently Asked Questions (FAQs)

What are the benefits of choosing a custom perfume bottle manufacturer?

Choosing a dedicated perfume bottle producer will bring out the product’s characteristics and uniqueness that it would not have had if not produced according to exact specifications. The range of custom-designed bottles may feature sizes such as 50ml or 100ml, and they may be made from different glass textures or come in totally unprecedented colors and textures. This level of individualization would make your perfume stand out in any market. Manufacturers also often have a policy of bulk selling, which usually means lower prices. If you cooperate with a respected perfume bottle vendor, you get the whole deal: the best quality of glass and compliance with the quality regulations.

How can I find wholesale perfume bottles for my brand?

The process of sourcing perfume bottles at wholesale for your brand requires checking out multiple suppliers in China or elsewhere with known quality glass production facilities. There is a wide variety of perfume bottle factories available. Some suppliers are so adaptable that they even provide both crystal and glass wholesale perfume bottles. The more you buy, the more you save. That is why it is advisable to buy as much as possible from the same supplier, whether crystal or glass. Suppliers with the capability to customize your item are to be chosen. Always insist on quality certificates to get excellent products.

What types of customization options are available for glass perfume bottles?

There are many options when it comes to customizing glass perfume bottles. Customers can request different sizes and shapes, as well as a wide range of finishing options. You might be looking for a spray bottle, a vial, or a stylish crystal glass, possibly with a brand logo, for example. Most suppliers also offer the service of making customized caps and labels, adding to the perfume products’ overall branding. A primary step in the customization process is selecting the designated glass type, whether high-quality glass or premium crystal. Going through the process of ensuring the quality of your glass bottles by conducting a series of stringent checks will make your product stand out even more among competitors.

What are the advantages of using OEM glass for perfume bottles?

Perfume bottle makers can be suppliers of glass, and this is how money and quality control come into play in production. Often, a glass of this nature is the result of very delicate, precise work to meet design needs; hence, brands can come up with unique, top-class offers. Moreover, the same OEM manufacturing methods can be used when the order volume is high, thus reducing the burden on brands related to inventory. The design freedom and the possibility of new bottle designs are two significant factors that make the OEM glass an inviting opportunity for the perfumery sector. Moreover, getting glass bottles from reputable manufacturers would mean they are crack-resistant and look good at the same time.