The fragrance industry treats its bottles as more than containers, as they serve as luxury indicators that convey brand identity and shape the first customer interaction. Emerging perfume brands, private-label manufacturers, and established distributors require wholesale suppliers of perfume bottles, as these products help them develop products that attract customer attention and establish brand connections with their intended audience.

The guide examines the top five wholesale perfume bottle suppliers, which offer distinct advantages through their product offerings and competitive positioning in the packaging market. Fuzhou Longlu Packaging Co., Ltd. has established itself as the leading company specializing in custom perfume packaging solutions. Fuzhou Longlu has earned its status as a dependable partner for brands seeking to enhance their fragrance packaging through its sustainable practices, premium materials, and wide range of customization options.

The article presents wholesale perfume bottle supplier options through its innovative design and sustainable practice features which will help you to make decisions that suit your brand objectives better. The guide provides solutions for you, whether you want bulk products at lower costs or you require custom designs that create a sense of premium value. The best industry experts will help us identify suitable suppliers to enhance our fragrance business operations.

Understanding the Market for Perfume Bottles

The perfume bottle market is expanding as more people buy fragrances, while packaging design is gaining greater importance. Consumers associate perfume quality with packaging which makes design and innovation essential for perfumes. People prefer sustainable packaging solutions and environmentally friendly packaging options because their understanding of environmental issues has improved. The market includes manufacturers that produce glass, plastic, and metal bottles, satisfying different customer needs at various price points. The market requires businesses to understand current trends in customer preferences, as these factors determine successful sourcing methods.

Current Trends in Perfume Packaging

The perfume packaging industry experiences a current transformation because customers now require packaging solutions that provide both functional value and visual appeal and sustainable environmental attributes. The leading design trend focuses on eco-friendly refillable packaging, as brands increasingly use reusable bottles and biodegradable materials to reduce their environmental footprint. The increasing use of recycled glass bottles demonstrates how luxury products can meet customer needs for waste reduction while maintaining their premium status.

The packaging industry now embraces minimalist packaging as its main trend which features elegant designs that support environmentally sustainable practices. Recent industry research shows that more than 60% of consumers now select either minimalist packaging or sustainable packaging because they observe others practicing environmentally responsible consumption. The current trend of personalization in packaging encourages brands to create custom packaging solutions which help them build stronger connections with their customers and increase customer retention.

Developments in smart packaging technology continue to drive its growing popularity among consumers. Brands today use QR codes and NFC technology in their packaging systems to give customers access to product details and authenticity checks and augmented reality content. The combination of technology and design creates interactive consumer experiences which help brands differentiate themselves from their market competitors.

The digital printing industry has developed new printing technologies which enable businesses to produce small quantities of products that feature personalized designs at reduced operational costs. The present trends show how the perfume packaging industry develops new packaging solutions which meet current consumer needs while sustaining ecological practices and technological advancements.

Types of Wholesale Perfume Bottles Available

Glass Perfume Bottles

The most popular choice for perfume bottles is glass because glass provides exceptional strength and glass maintains the scent of perfumes. The products offer multiple shape and size options which customers can customize through the selection of frosted glass and clear polished glass and detailed design elements.

Plastic Perfume Bottles

Plastic bottles operate as a cost-effective solution which offers customers multiple advantages because they possess both lightweight characteristics and shatterproof properties. The products come in multiple designs which include travel-friendly options that serve as a useful choice for various customers.

Metal Perfume Bottles

These bottles create a high-end contemporary appearance. The bottles which manufacturers create from aluminum and stainless steel materials provide outstanding defense against light-sensitive scents while delivering an opulent effect.

Rollerball Perfume Bottles

Rollerball bottles provide an easy-to-use travel solution which enables users to apply their perfume precisely. The products come in small dimensions which make them suitable for both testing purposes and individual use.

Atomizer Perfume Bottles

Atomizers deliver perfume as a fine mist which creates an equal distribution of scent throughout the room. The products combine functional performance with aesthetic appeal through their elegant designs which use glass and metal materials.

The Role of Glass in Fragrance Packaging

The packaging of perfumes requires glass because it provides both stylish appearance and practical protection which maintains the scent of the perfume. The properties of glass make it the perfect material needed to store and display perfumes. The following elements serve as primary explanations for selecting glass as the main material used in perfume packaging. The preservation of fragrance quality needs to be maintained through the selected packaging method.

Preservation of Fragrance

Glass functions as a non-porous and impermeable material which prevents any interaction between its contents and perfume while protecting the fragrance from external elements including air and humidity. The method guarantees that the scent remains unchanged throughout the extended period.

Aesthetic Appeal

Glass packaging creates a luxurious and sophisticated appearance which helps to establish the high-quality status of the fragrance. The design possibilities of glass enable brands to develop attractive bottle designs which draw consumer interest.

Sustainability

Glass stands as an eco-friendly material because it can be recycled in totality which makes it a perfect option for environmentally aware consumers and businesses that want to minimize their environmental impact.

Durability

High-quality glass bottles present both strength and protection against breaks which guarantees that products stay whole throughout their journey from production until they reach customers.

Versatile Design Options

Glass provides designers with multiple ways to customize their products through options that include embossing and coloring and frosted finishes and intricate patterns. The design elements enable brands to build their identity while developing packaging that customers will remember.

The multiple benefits of glass make it the preferred material for perfume packaging throughout the industry. The combination of practical features and aesthetic elements enables consumers to experience a better product which meets their practical needs and supports their brand identity requirements.

Top 5 Perfume Bottle Wholesale Suppliers

1. Fuzhou Longlu Packaging Co., Ltd.

Founded: 2005

Introduction: The company operates as a top Chinese manufacturer that develops high-quality customized perfume packaging products which include bottles and boxes and tops and sprays. They emphasize eco-friendly materials and sustainable production practices.

Main Products:

The company offers custom perfume bottles together with tester bottles and perfume boxes and caps and sprays.

Key Advantages:

- ✓ The company provides direct factory pricing.

- ✓ The customers can choose from multiple customization options.

- ✓ The company uses premium materials that undergo complete quality testing procedures.

- ✓ The company operates with environmentally friendly methods that support sustainable development.

Key Disadvantages:

- ✗ The company does not provide complete details about its minimum order quantity requirements.

Website: Fuzhou Longlu Packaging Co., Ltd.

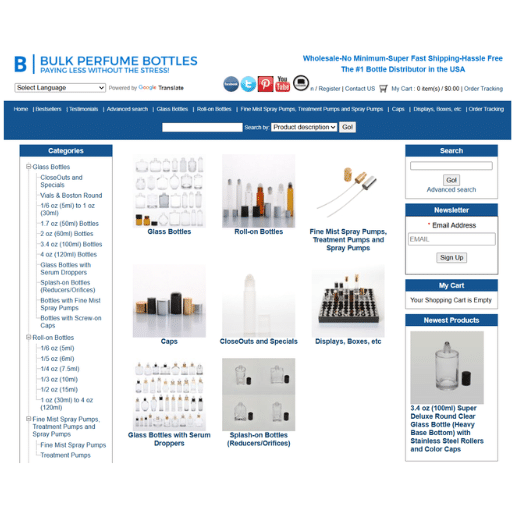

2. Bulk Perfume Bottles (Scentsational Shoppe)

Founded: 1995

Introduction: A US-based supplier offering a wide range of glass and plastic perfume bottles, roll-on bottles, and accessories. The company serves customers who require products from both small and large business operations.

Main Products:

The company sells glass bottles and roll-on bottles and fine mist spray pumps and caps and packaging accessories.

Key Advantages:

- ✓ The company has more than 25 years of industry experience.

- ✓ The company provides customers with a wide selection of bottle designs and sizes.

- ✓ The company offers lower prices for customers who purchase products in large quantities.

Key Disadvantages:

- ✗ The company provides fewer options for product customization than its competing suppliers.

Website: Bulk Perfume Bottles

3. Wuxi Lancy Beauty Technology Co., Ltd.

Founded: 2010

Introduction: A Chinese manufacturer specializing in glassware for cosmetic packaging, offering high-quality and customizable perfume bottles.

Main Products:

Glass perfume bottles, luxury caps, and custom packaging solutions.

Key Advantages:

- ✓ Strong focus on customization.

- ✓ Flexible pricing for bulk orders.

- ✓ Free samples for quality assurance.

Key Disadvantages:

- ✗ Longer lead times for custom designs.

4. Guangzhou Aboland Packaging Co., Ltd.

Founded: 2008

Introduction: The company operates as a leading vendor of glass perfume bottles and custom packaging solutions which showcase its inventive designs and environmentally sustainable business operations.

Main Products:

The company offers glass perfume bottles and travel bottles and custom packaging solutions.

Key Advantages:

- ✓ The company delivers products with superior craftsmanship.

- ✓ The company dedicates its efforts to environmentally sustainable practices.

- ✓ The company provides complete services for design and production processes.

Key Disadvantages:

- ✗ The minimum order quantity requirements for custom orders are set at a higher level.

5. Zuofun Cosmetics Packaging

Founded: 2012

Introduction: The Chinese supplier provides wholesale and custom perfume bottles which showcase its premium and eco-friendly design options.

Main Products:

The company provides glass perfume bottles together with atomizers and roll-on bottles and sample bottles.

Key Advantages:

- ✓ The company shows dedicated commitment to delivering high-quality visual elements.

- ✓ The company provides packaging solutions which combine sustainability with refillable features.

- ✓ The company offers its customers affordable rates when they purchase products in large quantities.

Key Disadvantages:

- ✗ The company restricts its international delivery service to specific regions.

Website: Zuofun Cosmetics Packaging

Importance of Supplier Relationships

The process of forming strong connections with perfume bottle wholesale suppliers stands as a vital factor which delivers three core benefits of reliable product quality and prompt product delivery and economical operations. Suppliers help brands to meet their production deadlines while they also help brands to maintain their product standards. A reliable supplier can also provide competitive prices which enable brands to maintain their industry profitability and competitiveness.

The following five factors show the essential nature of supplier relationships to businesses.

1. Consistent Quality Assurance

The use of high-quality perfume bottles serves as a crucial element which helps fragrance brands establish their premium brand image. A dependable supplier delivers high-quality materials and manufacturing expertise which guarantees that every bottle achieves the necessary quality standards. For example, brands that partner with reputable suppliers report a 20% reduction in defective packaging according to industry surveys.

2. Timely Delivery

Production delays will not happen because efficient suppliers deliver packaging components on time. Research shows that companies with strong supplier relationships experience 30% fewer supply chain disruptions compared to those with weaker connections.

3. Cost Efficiency

Customers of suppliers receive cost savings because suppliers pass savings from bulk orders and long-term contracts to their customers. Suppliers may provide their customers with either discounts or flexible payment options which help fragrance brands to manage their budgets better.

4. Access to Innovation

Leading suppliers often invest in research and development to create innovative designs or materials. Brands that maintain open communication with their suppliers can use the latest perfume bottle design trends which allows them to maintain a competitive edge.

5. Sustainability and Compliance

Suppliers become partners in sustainability initiatives through close collaboration with companies. Suppliers source eco-friendly materials while they meet environmental regulations which enables brands to fulfill their environmental obligations. According to recent industry data 40% of fragrance companies now collaborate with suppliers to reduce their packaging carbon footprint.

Fragrance packaging businesses need to establish supplier relationships as strategic partnerships which extend beyond mere financial transactions because these relationships drive long-term success.

Quality Control in Perfume Packaging

Quality control in perfume packaging functions as an essential requirement that businesses need to implement for both brand protection and customer satisfaction. The perfume industry needs businesses to develop their packaging standards due to rising market competition. The process of quality control requires multiple assessment stages, which test materials, designs, and final products against specific established standards.

The packaging must maintain its structural integrity throughout its entire period of use. The testing process for perfume bottles and carton packaging needs to cover all required aspects, which include evaluating their capacity to prevent leaks and shatter damage, and their performance during storage and transportation. The industry uses advanced technologies which include 3D scanning and AI-based inspection systems to identify defects in glass products that have irregular thickness and faulty sealing methods.

All factors share equal value with material quality. Leading brands now focus on using sustainable and recyclable materials which enable them to achieve eco-friendliness while maintaining their luxurious product design. A recent industry survey showed that more than 55% of perfume companies have switched to glass packaging which generates lower carbon emissions while using biodegradable materials for their cap and label adhesives.

The new quality control system establishes standard procedures for conducting sensory and usability evaluation tests. The packaging must maintain fragrance protection by shielding the product from light, air, and contamination. The “Journal of Packaging Technology and Research” report found that ultraviolet (UV) blocking coatings on glass bottles can extend fragrance longevity by up to 30%. The testing process for user-friendly designs which include ergonomic pumps and sprays aims to achieve maximum consumer satisfaction.

The data shows that organizations increasingly adopt digital tools for their quality assurance tasks. The AI-integrated quality control market in packaging will experience 18% annual growth from 2022 to 2027 according to global research firm Markets and Markets because of its precise and efficient error detection capabilities.

The combination of traditional quality control methods with modern technological solutions and sustainability initiatives enables perfume brands to preserve their reputation for quality while satisfying contemporary consumer needs. The quality control process for perfume packaging requires scientists and artists and responsible practitioners to develop their evaluation techniques.

Standards for Premium Glass Perfume Bottles

The design of premium glass perfume bottles must comply with strict requirements that ensure their performance through multiple testing methods. The following five essential standards establish the standard of excellence which needs to be achieved by this product category.

| Standard | Description |

|---|---|

| Material Purity | The production of premium perfume bottles requires the use of lead-free glass which meets high-quality standards to protect user safety while maintaining visual transparency. The glass purity provides both visual enhancement and chemical protection which stops any interaction between the glass and the perfume. |

| Dimensional Accuracy | The bottle design requires specific dimension measurements which include standard neck dimensions and wall thickness specifications to enable proper operation with both closure systems and spraying devices. The system operates as expected because of this exact measurement which also guarantees protection against leaks. |

| Resistance to Impact | The glass needs to meet both strength requirements and durability standards, ensuring it withstands impacts up to a specific level and protects against breakage during production, shipping, and customer handling. |

| Surface Finish | Bottles should have a flawless surface with no bubbles, scratches, or other defects. The product gains visual and physical appeal from its polished, smooth surface finish. |

| Environmental Sustainability | Manufacturers need to adopt sustainable practices that use environmentally friendly methods throughout their production processes. Modern sustainability standards require manufacturers to use recycled materials whenever possible and create bottles which can be completely recycled. |

The premium perfume packaging needs these standards to preserve its luxury value and product integrity.

Testing for Durability and Safety

The process needs to conduct durability tests and safety tests to confirm that premium perfume packaging meets both industry standards and customer requirements. The testing process evaluates the packaging’s ability to withstand various environmental and physical conditions while maintaining its aesthetic integrity and functionality. The following elements represent important components of this procedure.

Drop Testing

Drop testing simulates actual handling conditions which occur during regular operations. Glass bottles or packaging may face accidental drops during shipping, storage, or consumer use. The testing process requires dropping bottles from multiple heights which typically range between 1 meter and 1.5 meters to different surfaces for testing their breakage resistance. According to a recent industry standard for luxury packaging the minimum required drop survival rate must exceed 80% at a height of 1.2 meters.

Pressure Testing

Glass perfume bottles need to withstand both internal and external pressure forces to protect their structure during production, delivery, and customer handling. The equipment for pressure testing generates force to simulate actual pressure situations. A bottle must endure at least 2 bars of internal pressure during air travel to prevent leakage or explosion which occurs because of cabin pressure changes.

Temperature Resistance Testing

Perfume packaging undergoes high and low temperature testing to determine its performance in extreme climate conditions. The testing process evaluates material and adhesive and seal stability throughout the temperature range which starts at -20°C and ends at 50°C. The recent trend requires that materials should neither deform nor leak after continuous exposure to temperatures within this temperature range.

Chemical Resistance Tests

The packaging must demonstrate that there is no chemical reaction with the perfume ingredients, as these chemicals can either degrade the material or produce dangerous gases. The testing process requires the inner and outer materials to undergo extended testing with different perfume formulas. High-end packaging needs to meet less than 2% chemical compatibility failure rate according to the benchmark standard.

Recyclability Audits and Safety Certifications

Contemporary safety standards require testing for recyclability as a mandatory element which must accompany durability evaluations. The current ISO standards which include ISO 18604 for packaging and the environment mandate that production materials must meet international safety and sustainability standards.

The rigorous testing process allows manufacturers to confirm that premium perfume packaging meets high-quality requirements while satisfying customer demands for safe and environmentally friendly products. The assessment results become more accurate and dependable when advanced testing technology gets integrated into the assessment process.

Conclusion

The current fragrance market requires perfume bottle suppliers to provide more than basic container services which they previously provided. Packaging solution providers have achieved an innovative solution which combines effective product protection with sustainable environmental design and visually appealing elements. The best packaging suppliers for luxury products use sustainable materials and create custom designs which showcase their brands through their packaging solutions.

Fuzhou Longlu Packaging Co. Ltd. operates as a prominent leader in its industry because of its exceptional performance. The company has established itself as a reliable partner for brands that want to create a powerful brand presence through its dedication to premium quality production methods and environmentally friendly practices and extensive design customization. The design process results in bottles that function as essential elements of the perfume experience because the designers create bottles which combine luxury design with practical functions.

The selection of a supplier needs assessment of multiple factors which go beyond the basic cost aspects. The right supplier can help you create unique products that will make your brand stand out in the competitive market whether you run a new business who needs affordable solutions or an existing business which requires custom high-end designs. The future of fragrance packaging industry will develop through multiple growth opportunities which companies like Fuzhou Longlu operation.