The selection of perfume cap material requires careful consideration because it determines two important factors which include product appearance and operational efficiency and product lifespan and environmental consequences. The three materials that designers use most frequently are glass and zamak and sustainable resins because each material provides different advantages and characteristics. Which material works best for your brand needs and audience requirements? The article provides essential criteria which designers must evaluate when selecting materials through different material properties which impact both product design and manufacturing costs and environmental sustainability. The research will help you choose between premium product enhancements and sustainable design options and aesthetic product design and operational performance.

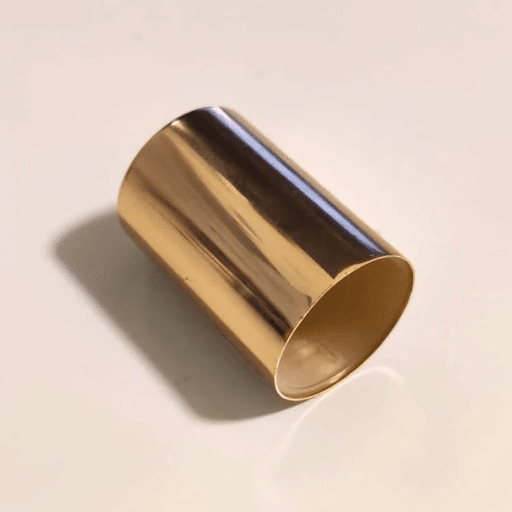

Zinc Alloy in Perfume Packaging

Zinc alloy serves as a popular choice for perfume packaging because it provides two essential benefits through its strong durability and visually appealing characteristics and versatile functionality. High-end brands can use the metallic finish because it provides their products with a premium appearance. The material demonstrates corrosion resistance which safeguards the packaging throughout its entire lifespan. The flexible characteristics of the material enable designers to develop complex patterns which designers need to create unique products that customers find visually attractive. Zinc alloy provides brands with an elegant design option that delivers both aesthetic value and operational effectiveness.

What is Zinc Alloy?

Zinc alloy exists as a flexible metal substance which industrial manufacturers use because its combination of zinc with aluminum and copper and magnesium delivers both strength and durability together with advanced casting capabilities.

Zinc Alloy Advantages for Perfume Caps

Durability and Strength

Zinc alloy provides exceptional durability which enables it to withstand extensive usage without becoming damaged. The design of perfume caps remains intact through their entire service life which results in extended product durability.

Design Flexibility

Manufacturers can use zinc alloy to create highly elaborate shapes which enable them to produce detailed custom designs. The branding unit develops specific cap designs which deliver an exact match to their brand identity and visual identity.

Corrosion Resistance

Zinc alloy naturally resists corrosion, making it ideal for protecting perfume caps from environmental factors such as moisture and humidity. The feature enables caps to maintain their original quality and looks throughout their entire service life.

Premium Look and Feel

Zinc alloy perfume caps acquire a premium appearance through their weight and surface finish. The product’s glossy metallic finish creates a luxurious effect which increases its value in the eyes of customers.

Comparative Analysis: Zinc Alloy vs. Other Materials

The process of selecting materials for testing perfume caps requires a direct comparison between zinc alloy and popular materials to confirm which material shows the best advantages and disadvantages. The assessment below shows five materials which people usually consider for this purpose and their performance comparison with zinc alloy:

| Material | Advantages | Disadvantages | vs. Zinc Alloy |

|---|---|---|---|

| 🧴 Plastic | The material weight is minimal and the price is affordable because it exists in large quantities and manufacturers can easily create different designs. | The product lacks the upscale appearance and texture of zinc alloy while its strength decreases and its recycling process becomes more difficult. | Zinc alloy establishes itself as the better material because it surpasses other materials in strength and visual appeal and environmental friendliness, which makes it suitable for premium products. |

| 🔩 Aluminum | The material is lightweight and protects against corrosion while maintaining recyclability. | The material’s softness causes permanent damage from denting and scratching, and it fails to deliver the weighty, upscale experience of zinc alloy products. | The public perceives zinc alloy as a more luxurious and stronger material than aluminum. |

| 🔮 Glass | The material features a luxurious, elegant design that is recyclable, while its contents remain safe due to its non-reactive properties. | The product is prone to breakage and weighs more than zinc alloy, making it more vulnerable during transportation and use. | Zinc alloy provides the same elegant appearance, but it offers better protection and easier handling. |

| ⚙️ Stainless Steel | The material provides outstanding durability, which protects against corrosion, and it delivers a contemporary look through its shiny surface. | The product becomes more expensive to manufacture because its weight exceeds that of zinc alloy. | Zinc alloy products show better visual appearance than their weight capacity and strength performance. |

| 🌿 Wood | The material displays an organic design that connects to nature, which becomes eco-friendly when wood is sourced through sustainable methods. | The wood material becomes vulnerable to water damage, which limits design options, and its rustic appearance makes it difficult to match all luxury branding. | The product offers greater design options and strength protection because it combines durability with an attractive appearance that matches high-end products. |

Verdict: The evaluation of these materials shows that zinc alloy matches perfectly with the requirements of durability and aesthetic range and environmental protection, which makes it the best material for luxury perfume caps.

The Different Types of Perfume Bottle Caps Need to Be Explored

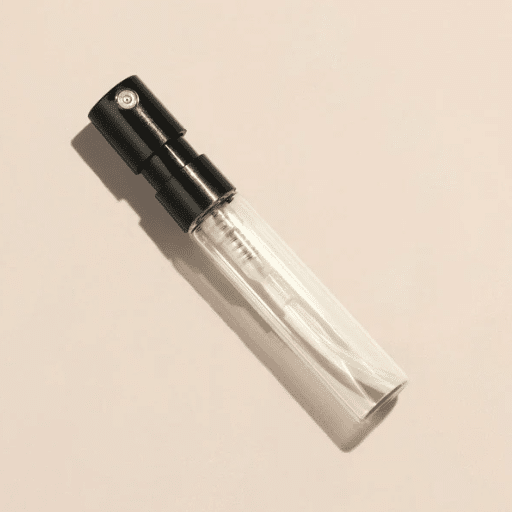

Perfume bottle caps come in a variety of materials and designs, each serving different purposes while influencing the overall aesthetic and functionality of the product. The following sections provide complete details about these main categories:

Plastic Caps

Plastic caps are widely used due to their affordability and versatility. The material enables the production of complex designs, which makes it a popular choice for mass-market perfumes. Recent trends indicate a growing focus on recycling and the use of biodegradable or recycled plastics to reduce environmental impact.

📊 Global sustainable plastic cap demand increased by 15% in 2023 vs. previous years

Metal Caps

Metal caps made from aluminum or zinc alloy represent the preferred option used in premium and luxury fragrance products. The materials provide an impression of refinement while also delivering strength. The material zinc alloy has become a popular material because it enables manufacturers to create complex designs while protecting products from corroding damage.

📊 Metal caps market expanded by 10% annually — zinc alloy represents ~60% of the market

Wooden Caps

Wooden caps are distinctive and eco-friendly, often used to create a natural and artisanal look for niche fragrances. Sustainable wood sourcing needs to become a priority for brands that want to connect with environmentally conscious consumers.

📊 70% of consumers would pay extra for sustainable packaging

Glass Caps

Glass caps provide an alternative to standard use, which high-end perfumes require because they need to match the sophisticated aesthetic of their glass bottles. Although the caps exude elegance, their weightiness and fragility create operational difficulties. Limited-edition products often feature glass caps, which enable brands to target collectors and fanatics.

Custom Mixed-Material Caps

Modern fragrance brands are beginning to experiment with mixed-material caps that combine metal, wood, and plastic. The combination enables designers to achieve exceptional results through their selection of materials, which creates a balance between functionality and attractive design elements.

📊 Composite perfume caps boost brand recognition by 20%

By combining innovative materials with cutting-edge design, perfume bottle caps have become as essential as the fragrance itself, shaping customer perceptions and reflecting brand values.

Overview of Perfume Cap Materials

The development of perfume cap materials has advanced since recent years because technological systems and eco-friendly practices and present design techniques have improved. Three primary materials constitute the components of perfume cap materials because metal and plastic and wood deliver distinct material advantages. The majority of existing brands adopt composite materials because these materials enable brands to create unified products that generate distinctive visual effects and functional characteristics.

🧴 Plastic Caps

The lightweight characteristics and multiple usage possibilities and inexpensive cost of plastic make it one of the most frequently used materials in various applications. Through injection molding technology, manufacturers can create products with intricate patterns that incorporate both essential shapes and advanced design features.

⚙️ Metal Caps

Luxury products use metals such as aluminum and zinc alloy and stainless steel because people associate these materials with high quality and strong durability. The caps deliver a premium appearance, which people commonly use for high-end unisex fragrances and feminine perfumes.

🌿 Wooden Caps

People prefer wooden caps because they give more value to their sustainable and natural material preferences. The wood material, which people obtain from responsibly managed forests, gives perfume packaging a natural look and a distinct character.

🔗 Composite Caps

Composite caps use wood and metal and plastic materials to produce hybrid designs which provide both functional capabilities and stylish appearance and environmentally friendly features. The design of the cap involves a plastic core that enhances its structural integrity, while a metal outer layer provides aesthetic value and a wooden section adds luxurious design features.

The main factor driving perfume cap material selection currently directs companies toward sustainable environmental practices. Companies conduct experiments with biodegradable plastics and recycled metal, and upcycled wood solutions to lower their environmental impact.

Designers create new packaging designs through their use of new materials and contemporary packaging methods which make perfume caps functional and attractive elements of fragrance packaging. Data-driven insights enable brands to make material choices, which help them create products, that fit their brand image and draw interest from contemporary customers.

💡 Sustainability Insight: A recent survey revealed that 74% of consumers prefer brands that demonstrate a commitment to sustainability, further driving innovations in material science.

Metal Perfume Caps deliver multiple benefits to their users

Durability and Longevity

Metal perfume caps deliver superior protection that endures for a longer duration when compared to the defense capabilities offered by plastic and wooden caps. The materials maintain their original appearance and structural soundness, which enables them to endure, through regular operation and direct strikes and outdoor conditions.

Premium Aesthetic Appeal

Metal caps possess weight and texture and surface finish attributes, which create an impression of luxury and advanced design.

📊 68% of consumers think products reach higher quality levels when packing materials contain metal caps

Recyclability and Sustainability

The recycling procedure for aluminum and stainless steel metal materials permits these substances to promote sustainability initiatives through their complete recycling process. Brands that use recyclable metal caps can boost customer loyalty and brand reputation because 74% of consumers choose brands that commit to sustainable practices.

Customization and Versatility

Metal caps provide extensive options for product customization through their multiple choices of engraving and embossing and anodized finishes. The organization enables brands to create their own visual branding through this flexibility, which permits them to design products that will attract specific customer groups.

Enhanced Functional Design

Metal caps create strong seals, which protect the sustainable packaging solution and maintain the fragrance product’s quality through protection against odor and wetness. The metal options enable users to operate the system without difficulty because they function properly with all types of dispenser systems.

Types of Custom Perfume Caps Available

The various custom perfume cap options allow brands to create distinct packaging solutions through their extensive design possibilities and material selection and product functionality. The product exists in three primary forms which include the following options.

| Cap Type | Description & Features | Market Data |

|---|---|---|

| ⚙️ Metal Caps | Fragrance designers select metal caps to use with their premium products because these caps deliver both durability and an upscale appearance. The manufacturers produce these items through the use of aluminum and zinc alloy and stainless steel materials which can be finished through embossing or debossing or matte coating methods. The metal caps protect against corrosion which results in enduring product performance. | ~30% of the global luxury perfume cap market |

| 🧴 Plastic Caps | The lightweight nature of plastic caps together with their ability to be reused multiple times makes these caps suitable for use with mass-market fragrances. The products come in multiple color options and multiple shape designs and two different texture types which include see-through and solid and shiny metal. The advanced molding techniques enable manufacturers to produce detailed products at affordable rates. | 45% of the market — most affordable for bulk production |

| 🌿 Wooden Caps | Wooden caps present an eco-friendly option that showcases its authentic natural beauty. The caps use high-grade woods that include oak and beech and ash to create two design options which include natural rustic appearance and polished refined appearance. | Market expanded by 10% annually driven by eco-conscious demand |

| 🔮 Glass Caps | Glass caps operate as a specialized product which has gained popularity through their application in both artisanal and niche luxury perfume markets. The bottle design provides a modern aesthetic which delivers substantial weight to the base of the perfume container. The glass caps feature detailed engraving and frosting designs which enhance their visual appeal. The demand for this product is increasing although it remains less preferred than other options especially in high-end product categories. | Growing demand in niche luxury & artisanal markets |

| 🔗 Decorative Hybrid Caps | Hybrid caps use metal and wood materials together with plastic and glass components to create striking design elements which attract shopper attention in stores. The cap system enables brands to exercise creative control which lets them develop distinctive packaging designs that make their products stand out from their competitors. | 12% industry growth projected over next 5 years |

| 🧲 Magnetic Caps | People increasingly choose magnetic caps because these products combine simple operation with modern design elements. The caps use magnets which create a secure closure system that provides users with a pleasant experience. The luxury perfume industry uses magnetic designs because they combine two elements which include easy use and sophisticated design. | Rising demand driven by luxury segment preference |

The various custom perfume cap types provide different functional and design options which help brands create special product identities that attract specific consumer groups while maintaining their competitive advantage in business.

Manufacturing Processes for Zinc Alloy Perfume Caps

Zinc alloy perfume caps undergo a production process which consists of multiple complex manufacturing steps that create products with high-quality results and precise dimensions and durable strength. The production process will be explained in this section which shows its main stages together with its key components.

Die-Casting

Zinc alloy perfume caps get created through the die-casting process which requires the injection of molten zinc alloy into a steel mold at high pressure. The process allows creators to develop complex designs which maintain their original dimensions through precise production techniques.

⚡ Modern die-casting creates caps in 5–10 seconds per cycle

Deburring and Trimming

The caps require deburring and trimming after die-casting because excess material and sprues and flashes need to be removed from the casting. Advanced robotic systems are sometimes employed for these tasks to achieve uniform edges and improve efficiency.

Polishing

The polishing process serves as an essential step which results in cap production that achieves flawless surface finishing. The industry employs multiple polishing techniques which include mechanical polishing and vibratory finishing methods.

🔬 Precision polishing reaches surface roughness of 0.8 Ra

Electroplating and Coating

The caps receive aesthetic and protective enhancements through the application of electroplating or coating techniques. Chrome, gold, and matte black plating serve as the most frequently applied finishes within the industry. The latest PVD coating advancements provide an environmentally friendly option which delivers exceptional durability.

📊 PVD-coated surfaces show 30–50% improved scratch resistance vs. traditional plating

Painting and Customization

The branding process requires companies to use customized painting solutions which help create caps that match their brand identity. Advanced spray-coating technologies, combined with UV curing systems, allow for vibrant, long-lasting color applications. The process enables the creation of decorative engravings and embossing which provides space to showcase logos and intricate designs.

Quality Control

The company conducts comprehensive quality assessments for every zinc alloy perfume cap to verify its structural strength and visual appeal and operational capabilities. The inspection methods use dimensional testing through coordinate measuring machines (CMMs) along with surface examination through high-resolution imaging tools.

Assembly and Packaging

The production process reaches its conclusion through the assembly of extra parts which include magnetic closures and rubber seals and inserts. The automated systems manage cap packaging which ensures contamination protection and damage prevention during the shipping process.

Key Data and Market Trends

The manufacturing process of zinc alloy perfume caps integrates engineering expertise with artisanal craftsmanship and environmental responsibility which enables brands to produce high-quality products that satisfy both visual and practical requirements.

How Zinc Alloy Caps are Made

The zinc alloy cap manufacturing process combines advanced engineering techniques with skilled craftsmanship methods. The production process consists of several main stages which we will now explain in detail.

Stage 1: Material Selection and Preparation

The project base material requires selection from premium quality zinc alloys. The Zamak alloy collection includes Zamak zinc alloys because they combine zinc with aluminum and magnesium and copper producing materials which offer both strength and flexibility and exceptional design abilities. The raw material undergoes inspection to confirm it meets the necessary purity standards and mechanical requirements which are essential for premium luxury packaging.

Stage 2: Die-Casting

The primary die-casting technique serves as the main method for creating zinc alloy caps. The operators inject the alloy into custom die molds after it reaches its melting point at 700°F (371°C) using high-pressure equipment. The process enables manufacturers to create accurate product shapes which maintain their original features through the process of delivering precise reproduction of all existing design elements.

📊 Die-casting achieves material usage levels reaching 95%, minimizing waste

Stage 3: Trimming and Polishing

The trimming process begins after the caps complete their casting and cooling phase which removes all extra material and flash that developed during the casting operation. The process of polishing follows this step which improves surface quality while making the base ready for upcoming coating and decoration processes. The industry commonly uses automated polishing machines to create consistent results throughout their operations.

Stage 4: Plating and Coating

Zinc alloy caps use their luxurious finish as a special characteristic which distinguishes them from other products. The process of electroplating produces a thin metallic coating which covers the surface with either gold or silver or chrome. The coatings feature protective components which help them withstand corrosive elements together with lacquer coatings which strengthen their ability to endure damage.

📊 ~75% of luxury perfume cap designs prefer metallic finishes for their premium aesthetic

Stage 5: Surface Decoration

The branding process requires surface decorations which include laser engraving and embossing and enamel color application. The advanced CNC machines create personalized engravings which produce distinct designs for each brand.

Stage 6: Quality Control and Assembly

The quality testing process examines finished caps before delivery to clients for testing their durability and color consistency and dimensional accuracy. The production process for zinc alloy caps maintains tolerance levels which remain within the ±0.05mm range to guarantee accurate bottle fitting. The quality inspection process concludes with caps being assembled together with liners and other necessary components.

The environmental impact of production methods used by luxury brands results in increased demand for zinc alloy caps which provide precise design and environmentally friendly production methods. The improvements in die-casting and plating systems have resulted in lower manufacturing costs while energy consumption dropped by 20 percent when compared to traditional methods.

Quality Control in Cap Manufacturing

The production process of zinc alloy caps requires quality control which serves as a fundamental element to ensure all products meet both industry standards and brand specifications. The process typically involves multiple stages which include inspecting materials and checking dimensional accuracy and assessing surface quality. Automated visual inspection systems together with coordinate measuring machines (CMM) operate as modern technologies which identify defects by precisely measuring both surface irregularities and dimension errors.

Real-time monitoring systems combined with AI-based systems for defect detection enable manufacturers to decrease waste by 30 percent while enhancing their operational efficiency. The functionality tests which assess liner adherence and proper threading determine whether the caps function as intended for their primary purpose of providing airtight bottle seals.

Many manufacturers nowadays implement eco-friendly practices to fulfill the current demand for environmental compliance within their quality control processes. The production process uses recycled zinc while emissions monitoring during quality checks meets carbon neutrality initiatives.

💡 Consumer Insight: Research shows that 60% of consumers prefer sustainable packaging, which leads brands to develop products using recycled zinc and compostable polymers. The present consumer demand for sustainable packaging options compels brands to create new products which incorporate recycled zinc and compostable polymers.

Customization Options for Perfume Caps

The fragrance industry now uses perfume cap customization as an essential branding tool which produces unique packaging designs that create lasting impressions. Companies use perfume cap customization to create distinct packaging designs which consumers will recognize as their brand identity. The following customization options show the most important options available for customization work.

Material Choices

The manufacturing process of perfume caps allows for the use of multiple materials which include metals and plastics and wood and eco-friendly materials which include bamboo and recycled content. High-end perfume manufacturers use aluminum and zamak metals to create their products that show luxury while sustainable companies prefer using materials that can either decompose or be recycled. According to recent reports, 60% of consumers show a preference for environmentally conscious packaging, prompting brands to innovate with materials like recycled zinc and compostable polymers.

Design and Shapes

Unique cap designs and shapes help establish a strong visual identity. Brands can choose between minimalist cap designs which create a streamlined appearance and detailed sculptural designs which create a permanent market presence. The fashion industry currently favors geometric cap designs which mimic floral and gemstone natural elements.

Personalization

Consumers now prefer to personalize their caps through the option to engrave their names or initials. Limited-edition bespoke caps serve as a strong selling point for brands which use this product during gifting seasons.

Color and Finish

Brands use bold, gradient, or metallic finishes to express their brand identities. The matte cap design offers an elegant appearance, while the glossy finish presents a contemporary design. UV coatings and anodized metal finishes have become popular because of their visual attractiveness and strong durability.

Sustainability Integration

Cap customization now features sustainable practices because consumers have become more aware of environmental problems. PLA (polylactic acid) and recycled PET materials have entered the market as popular bio-based material choices. The design of modular caps allows users to either reuse the product or replace parts, which helps decrease material waste and extends product lifespan.

Innovative Techniques

The combination of laser cutting and 3D printing and embossing technologies enables the creation of detailed designs for cap production. NFC-enabled caps have become more common because smart technology adoption has increased and these caps provide product authentication capabilities.

Customization work provides two benefits for perfume bottle design since it improves visual appeal and creates unique brand identities. Brand designers build customer loyalty by combining artistic expression with advanced features and environmentally responsible practices in their cap design work. The luxury perfume packaging market will achieve a 6.4% growth rate from 2023 to 2030 according to market studies which predict this growth will result from new customizable products and innovative packaging solutions.

Design Trends in Luxury Perfume Packaging

The packaging industry for luxury perfumes keeps developing through its use of daring design patterns and cutting-edge technological solutions which help it win over customers with refined tastes.

Trend 1: Sustainability as a Core Design Principle

The most important trend currently happening in the market involves companies selecting sustainable options for their material selection and operational procedures. Companies increasingly use sustainable materials which include glass and biodegradable plastics and responsibly produced caps to meet customer requirements for environmentally friendly products.

📊 60% of luxury consumers consider sustainability important when purchasing (McKinsey, 2022)

Trend 2: Personalization and Unique Identity

The growing demand for personalized experiences which create unique products has become an important trend. Consumers are drawn to products that resonate with their unique identities, and perfume packaging now often features customizable options such as engraving, bespoke color schemes, and limited-edition designs. Premium brands like Jo Malone and Dior offer customers the ability to personalize their perfume bottles through their customization services. The strategy has successfully built stronger brand loyalty while creating better experiences for consumers.

Trend 3: Technology Integration

Designers now consider technology integration as an essential element for their design work. Smart packaging solutions with QR codes or NFC chips provide consumers extra digital content which includes fragrance descriptions and origin stories and augmented reality (AR) visual elements. The developments enhance user interaction while providing solutions to the luxury market’s ongoing problem of counterfeiting.

Trend 4: Bold Aesthetic Choices

The year 2023 sees contemporary packaging designs which use bold visual elements as their primary aesthetic choice for luxury products. The market favors minimalist designs which use clean lines and monochromatic tones and abstract artwork because those elements create timeless fashion, while metallic accents and intricate textures and sculptural caps provide an opulent appearance.

The luxury perfume packaging industry will experience its main growth from emerging Asian and Middle Eastern markets which will create a 6.4% CAGR for the sector between 2023 and 2030. These regions showcase a growing interest in high-end products coupled with a willingness to spend on personalized and sustainable luxury goods. The luxury perfume packaging industry innovates through its combination of sustainability and personalized product offerings and technological advancements and aesthetic designs to meet the changing needs of consumers.

Current Trends in Metal and Glass Perfume Bottles

Metal and glass perfume bottles have become a central focus of the luxury perfume packaging industry, driven by a combination of technological advancements, sustainability, and consumer demand for aesthetic appeal. Design elements like caps and collars and accents now use metal components to create a premium appearance which designers find appealing. The industry favors stainless steel and aluminum because both materials provide excellent strength and recyclability.

📊 Market Outlook: According to market research, the global luxury glass packaging market is expected to reach $2.2 billion by 2030, fueled by high demand for premium fragrance presentations that prioritize elegance and environmental consciousness.

Glass bottles remain a signature packaging style for many luxury brands because of their clarity, weight, and sophistication. Companies are now innovating with lightweight glass technology, reducing the environmental impact while maintaining the premium feel consumers expect. Frosted or colored glass designs are trending, as they enhance visual appeal and reflect the personality of the fragrance inside.

Refillable glass bottles have become popular among consumers because major brands like Guerlain and Chanel support refill stations which aim to enhance reuse while minimizing waste. The beauty and luxury industries have embraced sustainability as their main guiding principle for future development.

The combination of metal and glass materials creates a packaging solution which delivers both strength and usability and visual appeal because modern consumers prefer environmentally sustainable products with beautiful designs. The combination of craftsmanship and sustainable materials establishes a lasting market presence for these materials in the luxury perfume packaging sector.

Importance of Aesthetic Design in Perfume Packaging

The perfume industry depends on aesthetic design because it determines how customers perceive products and select their purchases and brand commitments. The packaging of perfume products delivers more than just scent; it delivers the core identity of the brand which establishes an emotional bond with consumers. The five critical elements that demonstrate how aesthetic design matters for perfume packaging show its essential nature to perfume packaging design.

Brand Identity Expression

The packaging design shows the basic rules which establish the brand’s identity and core characteristics. The artistic and luxurious design elements of a product create a premium perception which enhances its market value according to consumer evaluations. The product packaging design uses complex design components to generate an impression of premium quality because it demonstrates high-level design expertise.

Customer Attraction

The first thing which attracts buyers to a product is its visual design. Research indicates that over 60% of buying decisions are influenced by packaging which makes aesthetic designs an essential requirement for products to achieve visibility on retail shelves.

Storytelling

A perfume bottle with good design will create an emotional experience which tells a complete story. The designers use material elements to create experiences which let consumers experience the main aspects of romance and boldness and traditional values through their combination of design elements.

Memorable Experience

The perfume achieves memorability through its distinctive artistic design elements. Consumers are more likely to keep and display beautifully packaged bottles which become decorative items and this practice increases brand visibility.

Sustainability Appeal

Eco-friendly consumer designs succeed because they use sustainable materials which include recyclable glass and metal components. The company improves its market position through brand enhancement which establishes trust with customers who support ethical business practices.

Perfume brands create packaging solutions which combine aesthetic design with essential consumer benefits through their combination of design elements. The combination of aesthetic design elements with functional elements enables perfume brands to develop packaging solutions which combine attractive design with essential consumer impact.

Eco-Friendly Innovations in Perfume Packaging

Eco-friendly innovations in perfume packaging have taken center stage as brands respond to consumer demand for sustainable and environmentally responsible products. The industry now develops sustainable packaging systems through its advancements in biodegradable materials and refillable packaging systems.

Biodegradable and Recycled Materials

Perfume companies now choose to use biodegradable packaging solutions which include plant-based plastic and compostable paper and recycled glass materials. The 2023 McKinsey & Company report found that more than 50% of beauty consumers prefer brands which use recycled materials for their product packaging. The perfume companies Guerlain and L’Oréal created bottles which use between 25% and 50% post-consumer recycled glass material to lower their environmental impact through waste reduction and resource conservation.

Refillable Perfume Bottles

The refillable packaging system functions as a sustainable waste reduction solution which unites luxury with environmentally friendly practices. The refillable bottle designs at store refill stations enable customers to refill their fragrances without buying new products according to Dior and Mugler. The method reduces packaging waste and operational energy expenses through the extended duration of fragrance bottle usage.

Innovations in Minimalism

The trend toward minimalistic packaging designs has become popular as companies work to simplify their operations and minimize their environmental impact. The removal of secondary packaging elements which include plastic wraps and decorative boxes enables companies to achieve substantial reductions in their material consumption.

Waterless Packaging Technology

The market now introduces waterless and solid perfume products which need less space for their packaging and storage requirements. The new development improves environmental sustainability because it decreases water consumption during production activities. Some brands produce solid perfume bars that eliminate the glass bottle completely to provide a sustainable option with minimal environmental impact.

The packaging advancements in the perfume industry demonstrate how the sector develops sustainable solutions which still maintain visual attractiveness. The future of perfume packaging development will showcase environmentally friendly innovations and sustainable production methods.

Frequently Asked Questions (FAQ)

How can I customize zamac perfume caps for a luxury custom fragrance?

You can customize zamac perfume caps using precision die-casting to create high-quality zinc alloy metal parts which can then undergo surface treatments through electroplate application and rose gold or shiny gold plating and matte black finishes and engraving. A cap manufacturer specializing in custom designs will offer customizable options like custom logo engraving, screen printed branding, 3D design molds, and strict quality control to ensure every perfume lid and cap perfume bottle meets luxury packaging standards.

What are the benefits of choosing a zinc alloy perfume cap or zamak perfume caps over plastic bottle lids?

Zinc alloy metal caps which include zamac perfume caps and zinc alloy perfume bottle fittings deliver advanced protection and premium weight capacity and improved metal finish adhesion for high-end metal finishes. The custom logo luxury engraving and screen printed patterns which they offer enable customizable options to their users while their products enhance the aesthetic appeal of a perfume glass bottle and round perfume bottle and support high-end fragrance branding.

Are zamac perfume caps compatible with standard perfume sprayer and spray pump systems?

The zamac and zinc alloy caps are specifically engineered to match standard sprayer and perfume sprayer systems. Cap manufacturers create precise perfume component parts for caps which their products through various spray pump systems. The cap manufacturers create their products to work with perfume oil and perfume spray and cosmetic perfume formulations.

Can I get a gold perfume or rose gold finish on a zamac perfume cap?

Absolutely. The electroplate techniques on zamac or zinc alloy caps enable the application of gold luxury and rose gold plating which serve as standard surface treatments. The project offers two surface treatment options which include aluminum perfume part plating and anodizing as well as the application of matte or shiny finishes that create upscale perfume glass bottle designs and allow you to develop unique perfume packaging.

What customization options are available for a cap square or round perfume cap design?

Manufacturers offer cap square and round perfume cap shapes with options for engraving and screen printed logos and custom logo luxury applications and 3D design molds and multiple surface treatments. You can request special features like a removable lid perfume cover decorative insets for perfume glass or internal fittings for spray pump integration to create a unique perfume presentation.

How does the die casting process affect the quality of zamac and zinc alloy perfume caps?

The die-casting process creates identical high-quality zinc alloy components which retain their complex design features for advanced custom applications and complete quality control assessments. The die casting process creates durable premium caps which distribute plating materials evenly to enable high-end metal coatings making them suitable for perfume glass bottle closures and perfume sprayer housings and customized packaging solutions.

Are there eco friendly options when choosing zinc alloy metal or aluminum perfume caps?

Yes, multiple manufacturers demonstrate their commitment to environmental sustainability through their adoption of recyclable zinc alloy metal and their execution of responsible plating methods and their creation of efficient die casting techniques which enable them to minimize waste. Aluminum perfume caps serve as a lighter recyclable option while manufacturers provide sustainable surface treatments and materials for their cosmetic packaging essential oil glass bottles and perfume glass bottle lines.

How do I work with a cap manufacturer to order wholesale luxury zamac perfume cap samples and open the mold?

Your task requires you to contact a cap manufacturer who specializes in custom and high-end perfume caps. You need to provide your 3D design or concept to request samples of the customized perfume lid and perfume cap options. The supplier will provide price estimates which cover the expenses of opening the mold and executing precision die-casting and plating and assembling the perfume sprayer or spray pump. The discussion will cover minimum order quantities for wholesale luxury runs and lead times and strict quality control measures and delivery arrangements for perfume glass bottle projects.

Summary

Making the Right Material Choice for Your Perfume Cap

Whether you prioritize durability, luxury aesthetics, environmental sustainability, or design flexibility — zinc alloy, glass, and sustainable resins each offer a compelling case. The ideal material depends on your brand values, target audience, and product positioning in the luxury fragrance market.