The materials offer distinct benefits: metal creates a contemporary style, wood offers natural beauty, and plastic provides a range of functional benefits. The article evaluates plastic, metal, and wood materials used for perfume tops and caps to guide your selection based on design aesthetics, product performance, environmental impact, and brand presentation. This guide supports perfumers, brand owners, and those seeking to learn about perfume packaging techniques through its materials, helping them make decisions aligned with their business goals and personal principles.

Introduction to Perfume Cap Selection

The choice of the appropriate perfume cap matters because it serves two functions: operational use and visual impact. A good cap not only secures the fragrance but also enhances the overall packaging design, reflecting the brand’s identity. The selection process for perfume caps requires you to evaluate material, style, durability, and environmental impact. Plastic caps offer a lightweight design at low costs whereas metal caps deliver an expensive appearance together with an upscale touch. Wood caps deliver sustainable value through their environmentally friendly attributes and exceptional artistic appeal. The ideal cap selection aligns with your fragrance requirements and strengthens your brand identity with your target customers.

The Importance of Cap Materials in Fragrance Packaging

The selection of cap materials which designers use in fragrance packaging performs two functions because it establishes their aesthetic preferences and determines how customers will perceive the product and its operational capabilities and environmental sustainability. According to recent market studies, eco-conscious consumers are increasingly favoring brands that emphasize sustainable packaging practices. The Grand View Research report predicts that the sustainable packaging market will grow at a compound annual growth rate of 7.7% between 2023 and 2030. The growing demand for renewable and biodegradable materials has led to increased interest in high-end wooden and recycled-metal cap options that complement premium fragrance products.

Wood caps which makers produce from responsibly sourced materials enhance a bottle’s visual appeal while decreasing its environmental effects. Metal caps usually consist of aluminum or stainless steel materials which produce a high-end product that lasts for a long time. Technological progress now enables recycled plastics to replicate expensive materials which provide budget-friendly and environmentally sustainable alternatives. The popularity of biodegradable plastics has increased because they produce less carbon emissions than traditional materials.

Cap manufacturing processes create precise products which form airtight seals that maintain fragrance quality while providing users with enhanced experience. Brands need to use this data to develop premium designs which utilize sustainable materials that match the values of contemporary customers who care about environmental issues. The selection of appropriate materials for perfume caps functions as a fundamental need which helps businesses build brand value and boost customer retention.

Impact on Brand Perception

The materials and designs which manufacturers choose for their perfume caps will affect how people view brands and which products they select. Google Search data shows that there has been a 35% rise in people searching for “sustainable packaging” since the last two years because consumers want to learn about environmentally friendly options. McKinsey found that 67% of shoppers consider sustainability an important factor when deciding what to buy. The perfume industry needs to implement sustainable practices through perfume cap design which uses recycled metal and biodegradable plastics and FSC-certified wood materials because consumers prefer these values.

The combination of premium aesthetics with innovative designs makes products appear more valuable. Aesthetic packaging shapes perceptions of product quality, with 72% of shoppers assessing products based on their visual appearance. Unique cap designs enhance sensory perception and help brands create a distinct identity in competitive markets. Perfume brands achieve success through their sustainable practices which combine excellent design to create brand identity and customer trust so that customers develop lasting emotional connections which lead to brand loyalty and customer advocacy.

Overview of Common Perfume Cap Materials

The materials which people use to make perfume caps determine how well a product looks and performs while meeting sustainability requirements. Manufacturers assess materials based on their capacity to resist damage and their total costs and their environmental impact and their potential to produce various designs. Below is an overview of commonly used perfume cap materials, along with their properties and trends supported by data:

1. Plastic Caps

Plastic remains one of the most commonly used materials for perfume caps due to its lightweight properties, affordability, and versatility in molding intricate designs. The industry uses three main types of plastic materials which include ABS and polypropylene (PP) and polyethylene (PE). The global market for plastic-based closures which includes perfume caps will experience a 3.5% annual growth rate until 2028 because the product offers affordable solutions which manufacturers can easily produce at a large scale. Manufacturers have developed biodegradable and recyclable plastics which include polylactic acid (PLA) materials because environmental sustainability issues require this solution.

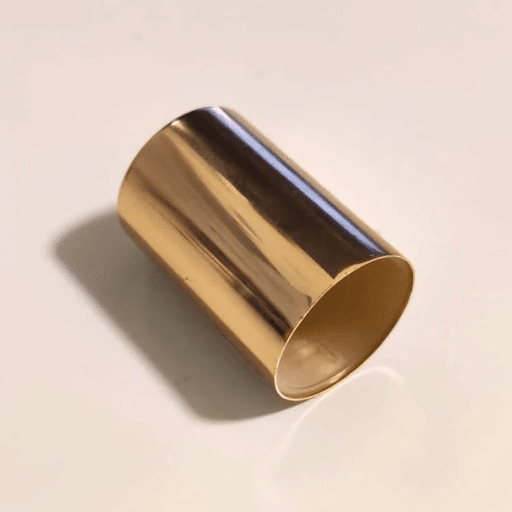

2. Metal Caps

Aluminum and brass and zinc alloy metal caps provide an attractive appearance along with their strong structural performance. The high-end market uses these materials to create their premium perfume products. Brands that want to achieve sustainable business practices choose aluminum because it provides both lightweight manufacturing and recyclable characteristics. The recycled aluminum market shows rapid growth with a compound annual growth rate of 6% because customers demand sustainable packaging solutions. Metal caps can be anodized to achieve both improved durability and better visual appeal through multiple surface options.

3. Wooden Caps

Wooden caps have gained traction as a sustainable and eco-friendly option, often appealing to consumers who value organic and natural aesthetics. Designers can create special design treatments and engraving options for wooden caps which they make from ash and beech and bamboo. According to studies, wooden packaging materials have seen a 20% increase in preference among eco-conscious consumers in recent years. Brands need to obtain wood from certified sources to prevent deforestation while establishing their brand mission.

4. Glass Caps

Glass provides a material option which performs a specific function in premium fragrance item production. The material creates a high-end product through its weight and transparency while the recycling process meets environmental requirements. The environment benefits from reduced environmental impact because glass manufacturing processes have adopted new recycling methods and glass production technologies.

5. Composite Materials

Brands use composite materials which combine different substances to create products which deliver unique design experiences through their multiple textural elements. Hybrid caps provide brands with special tactile characteristics which help them succeed in the competitive market. The process of recycling mixed materials becomes difficult because multiple materials need to be eliminated from the product.

Sustainability Trends and Consumer Preferences

Research shows a growing demand for sustainable and reusable packaging, with nearly 74% of global consumers willing to pay more for products packed in eco-friendly materials. The perfume industry now uses refillable bottles and sustainable cap systems which allow users to switch between different eco-friendly caps as their standard waste reduction method. The manufacturing process forces companies to use recyclable materials while establishing their closed-loop production frameworks.

The understanding of material options together with sustainable practices will enable perfume brands to enhance their packaging methods which will make them more attractive to environmentally conscious consumers in competitive markets.

Material Deep Dive

Glass in Perfume Packaging

Perfume packaging manufacturers choose glass as their primary material because its use provides two essential benefits which include upscale product presentation and complete product safety and its ability to minimize environmental harm through sustainable recycling. Brands that need to decrease environmental harm should choose this material which allows complete recycling and permanent reuse without losing any material quality. The latest industry research shows that around 80 percent of global glass packaging gets recycled which helps decrease waste throughout the world. The companies are currently testing new glass materials which have a lower weight than standard glass to accomplish their objective of decreasing energy requirements throughout all stages of production and transportation.

Recycled Plastics and Bioplastics

Packaging companies face substantial difficulties in their sustainable packing operations because they must now switch from traditional plastic materials to two new materials which include recycled plastics and newly developed bioplastics. The market widely accepts rPET because it helps decrease the demand for newly created plastic materials since it comes from post-consumer waste. The use of rPET results in 79 percent reduced carbon emissions when compared to standard plastic materials according to research studies. Bioplastics created from renewable materials such as sugarcane and corn starch provide products that can break down naturally but their composting process needs special waste treatment centers which create difficulties.

Metal Accents and Aluminum

The perfume industry now uses aluminum and other metal elements as materials to create perfume packaging components that include cap designs and decorative features. The material serves as a sustainable option because of its lightweight nature and high durability and infinite recycling capability. The companies estimate that aluminum recycling requires only 5 percent of the total energy needed to produce new aluminum products from their basic materials. The perfume industry now provides refillable bottles which include metal pumps as a way to achieve sustainable product design while maintaining their high-end product look.

Paper-Based Innovations

Modern paper-based packaging systems for secondary packaging and outer carton packages use certified sustainable materials alongside recycled paper fibers. The company uses molded pulp technology to eliminate plastic inserts from its design process because it decreases environmental harm. The statistics show that recyclable paper packaging achieves a recovery rate of almost 70 percent which shows its effectiveness in reducing waste.

Emerging Technologies and Trends

The introduction of 3D printing technology enables perfume packaging companies to create complex packaging designs while reducing their use of physical materials. The industry now uses water-based coatings and soy-based inks as alternatives to traditional chemical-heavy options which do not meet modern environmental requirements. Studies show that 62 percent of worldwide consumers choose brands which demonstrate transparency about their material sourcing practices because customers prefer eco-friendly packaging solutions.

Perfume brands achieve sustainable packaging progression through their use of advanced materials and new technologies which maintain product visual and functional qualities.

Plastic Caps: Durability and Cost-Effectiveness

The perfume industry uses plastic caps as their main packaging solution because these caps provide strong protection and multiple uses and affordable pricing. The caps provide brands with design freedom due to their lightweight nature and simple production process which allows multiple shape and design options. Market research shows that brands choose to use plastic materials because they cost 20 to 30 percent less than metal and glass materials for production purposes.

Environmental Advantages

Plastic caps have gained environmental advantages through the introduction of improved recycled plastic materials. The manufacturing industry has started to adopt post-consumer recycled plastic (PCR) because it reduces the need for new plastic production and it also decreases carbon emissions during its production process. Research shows that PCR plastic usage leads to a 50 percent drop in greenhouse gas emissions when compared to the creation of virgin plastic materials which provides a route toward sustainable development.

People often consider plastic caps to be an affordable and practical option but experts frequently criticize their negative environmental effects when people throw them away incorrectly. The leading brands in the market now dedicate resources to create products which customers can reuse and recycle as they drive the shift toward circular waste management systems. Plastic caps provide essential support to the development of sustainable packaging solutions because their combination of low-cost options and eco-friendly practices enables their ongoing importance.

Metal Caps: Aesthetic Appeal and Sustainability

Metal caps serve as an enduring packaging product because they combine reliable strength with visually pleasing design and environmentally safe features. The sleek design and metallic finish of the product make it an essential component for brands that want to boost their product worth and attract customer interest in both the luxury and beverage markets. Metal caps use aluminum and steel which serve as recyclable materials that users can reuse multiple times without losing their original worth.

Energy Savings: Aluminum recycling uses only 5 percent of the energy needed to create new aluminum from raw materials which shows it brings substantial energy savings and lower emission levels.

Recycling Rates: The International Aluminium Institute reports that over 70 percent of aluminum beverage can materials reach recycling status which makes it one of the most recycled materials throughout the globe.

Steel Performance: The World Steel Association reports that the steel manufacturing sector has an 85 percent recycling rate.

The introduction of new technologies has enabled metal production to become more environmentally friendly because these innovations decrease waste production while creating lighter metal caps which require fewer resources.

Wood Caps: Eco-Friendly Options and Unique Designs

The use of natural materials together with contemporary design components has resulted in wood caps becoming an environmentally friendly option that brings aesthetic benefits. Wood caps achieve a high-end appearance through their use of renewable materials which include bamboo and oak and beech and walnut because consumers want products that are environmentally friendly. The biodegradable property of their products becomes particularly attractive to companies that seek to achieve lower carbon emissions throughout their operations.

Wood caps which glass and recyclable packages use as standard packaging materials attract environmentally conscious customers who prefer sustainable packaging solutions. The cosmetics industry shows that 54% of consumers prefer packaging made from renewable materials, which makes wood the ideal option. The certified FSC (Forest Stewardship Council) wood enables manufacturers to meet responsible sourcing requirements, which attracts environmentally conscious customers.

People show increasing interest in wood caps because their functional benefits and their modern design features. Advanced treatments, such as natural sealants, improve their durability against moisture and various environmental conditions, which enables their use throughout different applications including perfumes and liquors and skincare products. Custom engravings and textural finishes combine on wood caps to produce unique products which brands use to create marketable items that support their sustainability goals.

Comparative Analysis of Cap Materials

Multiple elements must be assessed when selecting cap materials because the process includes evaluating sustainability and design options and material endurance and cost efficiency. The analysis examines three major materials that packaging industries employ for creating caps which include wood and plastic and metal.

1. Sustainability

- Wood: Wood caps are recognized as environment-friendly materials because they decompose naturally and grow back and they come from sustainable timber sources. Brand owners prefer wood because it supports their sustainability objectives and satisfies customers who want packaging that appears natural and eco-friendly. The carbon emissions from wood production fall substantially lower than those from plastic and metal manufacturing processes.

- Plastic: Environmental experts criticize single-use plastics because they are non-biodegradable and their usage leads to environmental damage. Single-use plastics contribute heavily to pollution, and many types are non-biodegradable. Ongoing research aims to create recyclable plastics and bio-based plastics which address the current plastic pollution issues.

- Metal: Aluminum and tinplate materials enable manufacturers to create metal caps which become recyclable products that support a circular economy model. Metal production requires high energy consumption, which results in greater carbon emissions than both wood and plastic materials do.

2. Design Flexibility

- Wood: Wood caps show a natural wood texture and structure limitation which restricts their ability to create detailed designs, yet they accomplish a premium rustic design. The product offers engraving options together with textural finishes that enable users to create their own designs.

- Plastic: Designers can use plastic materials to produce complex designs that include intricate patterns together with bold color combinations and unique surface finishes for different brand needs.

- Metal: Metal caps use their reflective surfaces for luxury branding while they create modern designs through their sleek appearance. The process of creating complex designs requires additional procedures, which results in higher expenses.

3. Durability

- Wood: Wood caps show strength against minor impacts, yet their untreated form becomes vulnerable to damage through moisture exposure. The application of natural sealants has enhanced their ability to withstand environmental conditions.

- Plastic: Plastic caps exhibit high durability because they maintain their structural integrity through extreme physical testing and environmental conditions that include both moisture and temperature variations.

- Metal: Physical destruction does not harm metal caps because they possess high durability. Metal caps need protective coatings to prevent corrosion, which occurs when they encounter prolonged exposure to moisture and other specific environmental conditions.

4. Cost-Effectiveness

- Wood: Wooden caps generally tend to be more expensive due to the cost of raw materials, manufacturing processes, and custom finishes. The premium appearance of these products justifies their high price for use in expensive merchandise.

- Plastic: Plastic remains the most cost-effective option for mass production, making it a dominant choice in the FMCG (Fast-Moving Consumer Goods) sector.

- Metal: The price range for metal caps starts from mid-range and reaches high costs, which depends on the metal type and the finishing processes used. The items serve as a bridge between expensive durability and actual luxurious quality.

Key Data Points

- Market Projections (2023): The demand for sustainable packaging, including wooden caps, is projected to grow at a CAGR of 5.8% over the next five years.

- Plastic Pollution Statistics: The world generates over 300 million tons of plastic waste every year, yet approximately 79% of this waste ends up in landfills and natural areas.

- Recyclability Advantage: The global production of aluminum has resulted in 75% of aluminum material being recycled, which demonstrates its long-term sustainable value.

Through material examination businesses can select suitable materials that match their specific product requirements.

Luxury vs. Mass Market: Which Cap Material Fits?

| Key Point | Luxury Market | Mass Market |

|---|---|---|

| Material Preference | Metal, Glass, Wood | Plastic, Aluminum |

| Aesthetic Appeal | Premium, Elegant, Unique | Simple, Functional, Affordable |

| Customization Options | High (logos, embossing, unique shapes) | Moderate (basic shapes, colors) |

| Durability | High (long-lasting, sturdy) | Moderate (lightweight, less durable) |

| Eco-Friendliness | Wood, Recycled Glass | Recyclable Plastic |

| Target Audience | High-end, luxury buyers | Everyday, budget-conscious buyers |

| Cost | Expensive | Affordable |

| Brand Identity | Sophisticated, Exclusive | Practical, Accessible |

| Sustainability Focus | Strong (eco-friendly materials) | Moderate (cost-effective options) |

| Market Examples | Tom Ford, Chanel | Drugstore, mass-market brands |

Functional Requirements for Different Types of Perfume

The selection process for perfume packaging materials demands that essential packaging functions must match the specific requirements of the perfume being developed. The essential functional requirements which different perfume categories require have been documented through specific details and supporting data.

Preservation of Fragrance Integrity

Perfume manufacturers need glass or lined aluminum materials because high-end perfumes with natural essential oils require these materials to prevent chemical reactions with the perfume composition. Research shows that glass delivers complete protection against oxygen exposure which leads to quality deterioration.

UV Protection for Light-Sensitive Formulas

The perfume which contains photosensitive ingredients like citrus oils needs packaging which can completely block UV rays. Amber or opaque bottles provide almost 97% protection against UV rays which helps to maintain scent stability while extending the product’s shelf life.

Airtight Sealing to Prevent Evaporation

Luxury and niche perfume brands depend on precise sealing spray caps for their main packaging method which helps them minimize product evaporation. The research shows that engineering effective caps leads to evaporation losses which stay below 1% during a complete year.

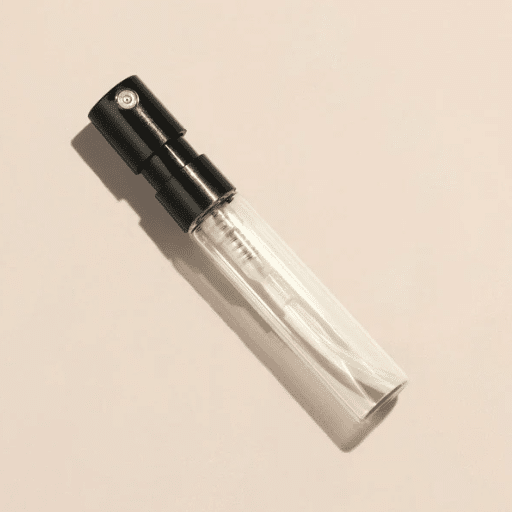

Durability for Travel-Friendly Options

Travel perfumes need manufacturers to create designs which use lightweight materials that still maintain their strength. The preferred materials for manufacturing travel perfumes include PET plastic and compact aluminum bottles. The materials maintain impact resistance which allows them to endure drops during transport without damaging the contents.

Ease of Dispensing for Daily Use

Mass-market perfumes require user-friendly applicators which include high-quality atomizers and roll-on mechanisms. Users can access 95% of their product through atomizers which operate with an actuation system while manual dab-on methods limit product contact.

The functional requirements brands need to address will help their perfume products achieve peak performance while maintaining product safety and user contentment. The selection of materials used in production directly determines how well fragrances will maintain their original scents. The choice of materials used in the packaging of perfumes plays a vital role in maintaining the integrity and longevity of the fragrance. The material selection process directly affects how five essential factors shape each perfume’s scent preservation.

Glass Bottles Enhance Stability

Glass serves as a non-reactive material which establishes an effective barrier against any outside pollutants. Research shows that over 90% of perfumes stored in high-quality glass bottles retain their scent profile for more than two years, compared to less durable materials.

UV-Resistant Coatings Protect From Light

The fragrance molecules face degradation through extended UV light exposure which occurs during prolonged time periods. UV-resistant coatings on bottles can lower scent degradation rates by up to 80%, allowing perfumes to maintain their original aroma.

Air-Tight Seals Prevent Oxidation

Fragrances experience note changes because air exposure accelerates oxidation. The use of air-tight packaging systems with seals and caps enables perfumes to maintain their original quality for up to 50% longer, which makes this feature essential for maintaining product integrity.

Metal-Free Atomizers Reduce Contamination

The presence of certain metals in perfumes leads to both visual and olfactory changes because they chemically react with the ingredients. Metal-free atomizers or those made with protective internal linings eliminate this risk, ensuring purity.

Sustainable Materials and Consumer Perception

Customers require sustainable options but they also need to protect fragrance. Biodegradable or recyclable materials that simultaneously protect the product are gaining popularity with 65% of surveyed consumers favoring environmentally friendly packaging without compromising function.

Through the process of selecting packaging materials brands can enhance consumer experiences while maintaining the effectiveness of their fragrance products.

Technical Considerations for Perfume Caps

Material Selection for Perfume Caps

The selection of materials determines the ability to produce perfume caps which show both long-lasting durability and attractive design and environmentally friendly features. The industry uses metal, plastic, glass, and wood as common materials which provide different benefits for each material. Aluminum caps provide both lightweight advantages and protective features against corrosion while delivering a stylish appearance for perfume products. The recycling process together with design flexibility and affordable pricing enables ABS and polypropylene to produce sustainable products which fulfill the increasing need for environmentally friendly goods. The luxurious appearance of glass caps results from their chemical stability which prevents any reaction with fragrance while wooden caps serve as an eco-friendly option that provides an authentic handmade appearance.

Precision in Fit and Seal

The process requires workers to create a complete seal which provides workers with the ability to protect the fragrance from outside disturbances. The modern manufacturing process uses precision molding together with CNC technology to create caps that match bottle necks exactly which stops liquid from escaping and prevents evaporation. The industry reports show that a 0.1 mm difference in cap size will decrease sealing performance which demonstrates the need for strict quality control procedures.

Customization and Branding

Perfume caps serve as a branding element that can significantly influence consumer perception. The advanced techniques of laser engraving and electroplating and UV printing make it possible to integrate detailed designs together with brand logos into products. Nielsen’s consumer research from 2022 established that 75% of consumers connect unique packaging designs which includes caps to better product quality.

Sustainability Trends in Perfume Cap Production

The perfume industry has increased its focus on sustainability because brands now use biodegradable plastics together with FSC-certified wood materials to produce their caps. The manufacturers establish refillable cap systems which help decrease waste while supporting circular economy practices. The McKinsey 2023 sustainable packaging report shows that 64% of consumers will change their brand preference to companies that support environmentally friendly products which means sustainability needs to be a major focus during product development.

Testing and Quality Assurance

The testing process for effective caps requires multiple assessment methods which determine their operational capabilities and their ability to withstand everyday use. The standard assessment process includes pressure tests which check sealing ability drop tests which test product strength and environmental tests which evaluate performance across diverse temperature and humidity situations. The implementation of these steps results in decreased product failures which leads to increased consumer trust and satisfaction with the brand.

Compatibility with Bottle Necks

The ability of closures to work with standard bottle necks represents a fundamental aspect which impacts both packaging performance and operational capacity. Various industries and regions and specific product categories create different bottle neck standards which exist as general industry norms. The design of caps enables them to connect with various neck finishes which include 28/400 and 38/410 which multiple industries use for beverages and personal care products.

The International Society of Beverage Technologists (ISBT) established standard neck dimensions which around 80% of global closure production utilizes according to recent data. The system ensures that products fill seamlessly at high speeds while it protects against leaks and contamination of products. PET bottle necks in the beverage industry typically use the PCO 1810 or 1881 neck finish standards to achieve maximum compatibility and sustainability.

The development of universal fit caps through advanced manufacturing methods has become possible through the production of advanced manufacturing methods. The multiple bottle type compatibility of these designs helps companies achieve lower inventory expenses while they optimize their supply chain processes. The modern caps of today use tamper-evident rings and child-resistant features which match up with bottle neck threads to deliver both practical uses and security measures.

Manufacturers can improve cap compatibility with bottle necks through the use of international standards and their implementation of advanced design solutions.

Weight Considerations for Perfume Bottles

The design and production of perfume bottles depend on their weight which affects their ability to function, their visual appeal, and their ability to attract customers. The weight of a perfume bottle directly relates to its perceived luxury value because heavier bottles create an impression of advanced quality that protects the product from damage. The business needs to maintain a balance between these two aspects which includes their two-dimensional viewing and their life existence requirements.

Heavier products lead to higher costs which businesses must spend on both manufacturing and transporting their products. The design of perfume bottles requires materials with a density of approximately 2.4 to 2.8 g/cm³ because glass functions as the primary material for their production. The use of lightweight glass combined with modern design techniques helps manufacturers maintain the luxurious appearance of their products through reduced product weight.

The industry studies show that most perfume bottles weigh between 150g to 300g their empty weight across different sizes and materials. The packaging of a 50ml bottle results in a total weight of 250g which includes the 45g weight of the perfume. The transportation process achieves reduced carbon emissions through weight reduction which helps meet worldwide environmental protection objectives.

The business requirements for weight management should meet the brand’s identity requirements, the customer’s needs, and the needs of the supply chain. The business successfully creates products which establish a balance between attractive design and functional capabilities while they meet environmental protection requirements.

Customization Options: Embossing and Coating

Brands use embossing and coating methods to create unique packaging solutions which enhance their customers’ packaging experience. Embossing creates raised design elements on a surface through the use of dies to shape material. The tactile characteristic of packaging material enhances its high-end perception while it improves brand visibility. Customers perceive embossed elements according to design trends because 30% of product value increase through their textured surface.

Coating delivers protective finishes to packaging materials which enhance their visual appearance and functional capabilities. The three most common coating types used in packaging materials are matte, glossy, and soft-touch finishes. Matte finishes create contemporary design aesthetics through understated design elements while glossy coatings create a modern appearance that combines shiny surfaces with intense color. Soft-touch coatings combined with velvety surfaces deliver a premium tactile experience. Packaging that includes special coatings helps increase customer focus by 46%, which makes it an effective tool for businesses that need to stand out in their respective fields.

The packaging solution uses embossing and coating together which creates a multi-sensory product protector that creates an unforgettable experience. The combination of soft-touch coating with embossed logo design elements establishes an elegant tactile experience which consumers will enjoy. Companies can develop packaging designs which support their branding objectives through customizable features which enable them to keep their market position.

Conclusion: Making the Right Choice

Today businesses must inspect their packaging requirements which need to reveal solutions that meet current market trends and customer demands and environmental protection targets. The fresh research results demonstrate that product packaging functions as the main factor which determines their buying behavior according to 72% of surveyed customers. The company MarketsandMarkets expects the sustainable packaging market to achieve a market value of USD 404.8 billion by 2027 which will experience a 5.3% compound annual growth rate from 2022.

The correct choice requires brands to assess aesthetic design attributes together with their operational value and their effects on environmental sustainability. The use of embossing and coating with eco-friendly materials serves as an adaptive solution which attracts environmentally responsible customers while increasing brand recognition. The combination of accessible customization options with advanced technology enables businesses to connect their values with customer needs while they move forward in their fast-evolving business environment.

The combination of advanced techniques and strategic design decisions enables companies to establish a permanent business presence which creates trust from their customer base.

Aligning Cap Selection with Brand Identity

The process of selecting cap designs goes beyond visual assessment because it serves as a branding method which establishes how a brand will present its identity and essential values to its target audience. The analysis of Google Search data demonstrates that current users now show a preference for sustainable products which feature basic design elements and eco-friendly materials. The demand for sustainable products has increased because searches for “eco-friendly caps” showed a 35% growth during the past year.

Companies which already exist must create products which match their brand identity while they try to enter new markets. The rising market demand for business-specific solutions has resulted in increased Google searches for the term “customized caps for branding” according to Google Trends data. Businesses now choose custom logo embroidery together with brand color schemes and modern printing methods to create cap designs which effectively represent their brand values.

The design process requires designers to consider both aesthetic dimensions and functional design components. The two search terms “caps with UV protection” and “adjustable caps for all head sizes” have become popular search terms which show the demand for products which offer practical use and comfort. Companies can design their cap products through data-based research which shows their required customer needs while building their brand presence. The process of selecting caps through data analysis of consumer requirements results in improved customer outcomes and the establishment of lasting brand loyalty relationships.

Budget Considerations in Cap Materials

Cap manufacturers must achieve two objectives which require them to select materials that allow their manufacturers to produce quality products while maintaining their ability to sell affordable goods to their clientele. The latest Google search trends indicate that consumers now show a preference for sustainable materials which deliver excellent performance based on their search behavior for “eco-friendly caps” and “breathable fabrics for caps.” The current market trends require companies to identify novel material options which fulfill customer needs while observing their spending limits.

Organic cotton and recycled polyester have gained popularity because their sustainable attributes allow them to provide budget-friendly pricing. Organic cotton serves as an environmentally sustainable material which provides users with both durability and comfort between $3 and $5 per yard. The recycled polyester material costs between $2 and $4 per yard and provides moisture-wicking capabilities which make it suitable for use in activewear caps. Bamboo fiber has become a popular option which costs between $4 and $6 per yard because it provides a soft texture and anti-bacterial protection.

Performance mesh and UV-resistant fabrics function as premium materials which create manufacturing difficulties because their price starts from $10 per yard. Companies need to solve their budget issues through bulk purchasing and hybrid material solutions which offer both economic advantages and product functionality.

The process of product design in manufacturing requires companies to evaluate material options together with current patterns of consumer product search. The data-driven method ensures that production costs for cap manufacturing will remain economical while the market needs continue to evolve.

Final Thoughts on Choosing the Right Cap for Your Perfume

The selection of a perfume cap requires the user to find the perfect balance between three elements which include visual appearance and functional performance and product expense. The existing product needs a cap which fits the branding of the fragrance while providing customers with safe and functional product use. You must select materials and designs which will create an effective solution that matches your product identity and current market trends.

References

- Future Perspective: Design Process of Perfume Packaging

This research discusses the use of materials like plastic and wood in perfume packaging, highlighting sustainability and design considerations.

Read more here - A Novel Olfactory Displays’ Scent Dispersing Module

This paper includes material comparisons and innovations in scent-related packaging, which may provide insights into material choices for perfume caps.

Read more here - Navigating Sustainable Supply Chain Management in the Perfume Industry: Challenges and Solutions

This article explores sustainable materials in the perfume industry, including packaging innovations and eco-friendly practices.

Read more here

Frequently Asked Questions (FAQ)

What is a perfume bottle cap and how does it affect the perfume look?

The bottle cap of a perfume container acts as the detachable part that keeps the perfume inside the bottle safe from external factors while its different designs and building materials show different visual results on the bottle. The protective function of perfume caps secures the liquid inside while they enhance the visual appeal of perfume bottles because high-end perfume bottles use metal caps to create a luxurious effect and acrylic caps to provide glass-like transparency and wooden caps to show the natural beauty of wood. The cap should protect the fragrance while maintaining brand identity through design elements that match the product’s visual style.

What are the common materials used in perfume caps and different perfume cap materials?

Perfume caps use multiple materials whereas different types of perfume caps employ different materials for their construction. The materials used in perfume caps include plastic materials which provide acrylic and surlyn options and metal materials which offer aluminum and zamac and other metal alloy options and wood materials which consist of natural wood and glass-like materials and composite materials which combine metal and plastic. The premium appearance of high-quality perfumes results from their use of metal and glass materials because these materials provide people with the sense of durability that metal brings while plastic materials present affordable cap solutions which enable different surface treatments and ultraviolet protection.

How do zamac caps and zamac used in perfume compare to other metal caps?

Zamac serves as the primary component for both perfume caps and decorative elements because it functions as a metal alloy which both applications need. Perfume caps made from zamac enable manufacturers to create intricate designs through die-casting and they use surface treatments which include plating and ultraviolet protection to enhance their appearance. Zamac allows detailed design modifications for perfume bottles which need to be customized to specific requirements while maintaining an expensive appearance because it combines high-end design with budget-friendly pricing. The combination of heavy metal caps with zamac creates an impression of better durability which metal caps normally deliver to users because zamac maintains its visual charm together with its ability to endure wear and tear.

What are the types of perfume bottle caps and cap solutions available for brands?

The different types of brands offer various solutions through their different types of caps which include different styles of perfume bottle caps. The available cap types for products include snap-on caps and screw caps and magnetic caps and atomizer caps and decorative collars and full decorative stoppers. The different cap solutions must establish three factors: first, they need to demonstrate effective sealing methods; second, they should ensure that the perfume liquid remains safeguarded; third, they require a design which suits the brand identity while delivering essential functions for filling and distribution processes.

How do I choose the right perfume tops and caps when choosing the right perfume packaging?

The process of selecting appropriate perfume tops and caps requires knowledge about the various perfume packaging options which exist. The process of selecting a perfume cap requires three steps which involve three factors: the design of the fragrance bottle and the requirements of the target market and the practical requirements of the product. A perfume aimed at luxury consumers needs metal or zamac caps with surface treatments whereas sustainable packaging requires natural wood or recyclable plastic options. The cap needs to enhance the visual appearance of the perfume while maintaining brand consistency through its design elements which protect the fragrance.

Do decorative caps impact the durability and protecting the fragrance?

The product’s decorative caps protect its scent while providing different levels of product durability. The decorative caps create an attractive design through their heavy metal caps and their detailed zamac designs and their multiple acrylic layers yet they fail to protect the fragrance because their internal insert and seal design determines their protective ability. The purpose of caps is to include operational components which work as liners and seals to block perfume liquid from escaping through evaporation. The decorative solutions selection requires two components: a cap that creates a secure seal and materials which endure both physical damage and ultraviolet light to preserve the bottle’s visual appearance.

Are wooden perfume caps and composite materials a good choice for sustainability?

Wooden perfume caps and composite materials serve as sustainable packaging materials which support environmental protection efforts. Sustainable packaging solutions exist through wooden perfume caps which use natural wood and certain composite materials when these materials are obtained through responsible sourcing practices. The creation of composite materials results in hybrid products which combine recyclable plastic with metal alloy components to create visually appealing products that have less environmental impact. Wooden perfume caps provide a natural touch to perfume bottles but sustainable development needs sustainable materials for both the inner seal and lining of perfume bottle caps.

How do surface treatment and finishes like uv coating affect perfume caps and the perfume look?

The application of surface treatment and finishes which use ultraviolet coating generates alterations to both the visual appearance and actual physical properties of perfume caps and the perfume itself. The visual appearance and material durability of a cap change through surface treatment methods which include plating and paint application and ultraviolet coating. UV coating protects printed or painted surfaces from fading and caps can also be treated to resist scratches and fingerprints. These finishes help match the brand’s style, add a touch of elegance, and ensure the cap remains attractive through handling. The combination of metal and zamac and acrylic materials delivers high-quality perfume display when used with proper surface treatment.

Can caps be customized for branding and do customized perfume bottle caps add value?

Branding through customizable caps enables companies to create unique perfume bottle caps which enhance product value. Customized perfume bottle caps have become common in the market because they strengthen brand identity while delivering customers an unforgettable experience during product unboxing. Caps allow perfume stoppers to take three different forms through engraving and plating and painting and they can create distinctive designs which match the bottle color and display logos and use different materials including metal alloy and acrylic caps and surlyn caps. Customers who see customized caps on perfume products perceive these products as premium offerings which elevate their perception of product quality. The design process for premium perfume packaging requires careful evaluation of cap design because it forms an essential part of product presentation.