One may think of the process of rock drilling as a rather formidable and complex task; however, with the basic knowledge, appropriate equipment, and proper skills, tasks may be made easier and more efficient. Whether a professional engaged in construction or mining projects, or a DIY project enthusiast attempting a rock removal assignment, it is crucial that the basic principles are familiar with the ideas of rock drilling.

What You’ll Learn: This comprehensive guide covers everything from essential tools and safety precautions to step-by-step drilling procedures and best practices for different rock types.

Essential Tools and Equipment for Rock Drilling

Primary Drilling Equipment

Rotary Drill or High-Performance Rigid Machine

To dig deeper into a rock surface, you need a high-performance rigid drill machine. They are fitted with advanced technology to make them tough and easy to run.

Drill Bits

High-performance rocks need the right technology to be quick and easy to break down. With these kinds of rocks, it is crucial to have drill bits like diamond- or carbide-tipped, which are the most suitable in terms of efficiency and cost.

Air Compressor

A lot of the time, air drills require an air compressor in order to obtain the right air pressure and achieve the desired results.

Safety and Support Equipment

| Equipment Type | Purpose | Key Features |

|---|---|---|

| PPE (Personal Protective Equipment) | Worker safety | Hard hat, gloves, safety goggles, ear protectors, steel cap boots |

| Cooling/Lubrication System | Prevent heat build-up | Preserves drill bits, maintains efficiency |

| Dust Management System | Workplace safety | Water mist, dust suppression equipment |

Types of Drilling Machines

Rotary Drilling Machines

Often used in the extraction of solid deposits in large-scale mining and geological exploration. Their operational principle is to excavate the solidly deposited rock, with drilling liquids serving as means of rock release and cooling.

Impact Drilling Machines

These machines serve as artificial hammers and are notably used in drilling into brittle rock formations. Machine capabilities vary based on differences in rock hardness.

CNC Drilling Machines

Computer numerical control systems that produce holes with high geometric and dimensional accuracy, benefiting industries with better productivity and fewer construction errors.

Wireless Drilling Machines

New-generation drills used for drilling in areas with limited space and work that demands flexibility.

Magnetic-based Hole Making Machines

Primarily used in metalwork, offering precision and balance when working with ferrous metal surfaces.

Choosing the Right Drill Bits

| Drill Bit Type | Best For | Key Advantages |

|---|---|---|

| High-Speed Steel (HSS) | Wood, plastic, soft metals | General purpose, cost-effective |

| Cobalt Bits | Stainless steel | Exceptional heat resistance |

| Titanium-coated | Multiple materials | Durable, resistant, long-lasting |

| Diamond-coated | Electronics, precision work | Extremely precise, durable |

Safety Gear and Accessories

⚠️ Critical Safety Requirements

- Safety glasses: Protect against high-speed foreign materials

- Heavy-duty gloves: Essential for grip and hand protection

- Ear protection: Mandatory for noise levels over 85 decibels

- Respiratory protection: Prevent inhalation of harmful dust particles

Step-by-Step Instructions for Drilling Rock

1Site Preparation and Safety Assessment

- Evaluate the site for potential risks

- Clean up debris from the work area

- Ensure all personnel wear appropriate safety equipment

- Identify special requirements for different rock types (e.g., granite)

2Select Appropriate Drill and Drill Bit

- Choose heavy-duty rock drill for dense, hard rocks

- Consider rotary hammer or pneumatic rock drill

- Select carbide-tipped or diamond-tipped bits for optimal performance

3Mark Drilling Areas

- Measure and mark exact hole locations

- Use permanent marker for clear visibility

- Maintain accurate spacing between drill points

- Ensure alignment with project specifications

4Position and Secure the Rock

- Clamp removable rocks securely

- Position drill perpendicular to marked surface

- Avoid side-drilling to prevent equipment damage

5Execute Controlled Drilling

- Start at lowest possible speed

- Gradually increase speed as drilling progresses

- Maintain consistent cutting speed

- Use lubricants or water for heat management

6Clear Debris Regularly

- Remove drill bit periodically to clear accumulation

- Keep drilling pathways clear

- Use compressed air for efficient debris removal

- Prevent clogging for maintained efficiency

7Final Inspection

- Measure every drill hole against specifications

- Double-check measurements with measuring tape

- Make careful adjustments if needed

- Ensure holes meet safety standards

Safety Precautions When Drilling Rock

🛡️ Essential Safety Protocols

Personal Protective Equipment (PPE)

- Fire-resistant suits

- Chemical-resistant gloves

- Steel-toe boots

- Advanced materials like Nomex or Kevlar for extreme environments

Respiratory Protection

- HEPA-filtered respirators for airborne contaminants

- Real-time air quality monitoring

- Supplied breathing apparatus when necessary

Advanced Safety Technology

- Smart helmets with impact detection and communication

- Anti-mist, scratch-proof eyewear

- Industrial-grade noise-cancelling equipment

Hazard Identification

Smart hazards fall into four primary categories:

- Physical hazards: Unsafe equipment, unmanaged noise impact

- Chemical hazards: Exposure to harmful substances

- Biological hazards: Bacteria, viruses in work areas

- Ergonomic hazards: Work strain and repetitive motions

Common Mistakes to Avoid

| Mistake | Consequences | Prevention |

|---|---|---|

| Wrong drill bit selection | Inefficiency, equipment damage | Match bit to rock composition and hardness |

| Poor maintenance | Safety hazards, decreased efficiency | Regular servicing, lubrication, part replacement |

| Incorrect speed/pressure | Bit damage, poor results | Adjust parameters based on rock composition |

| Ignoring cooling systems | Overheating, increased wear | Proper coolant/lubricant usage |

| Poor alignment | Path deviation, equipment damage | Proper setting and stabilization |

Best Practices for Effective Rock Drilling

Pre-Drilling Assessment

Geological Evaluation Benefits: Analysis of stratigraphy, fault lines, and groundwater conditions allows drillers to select appropriate technology and minimize risks.

Technology Integration

- Use core sampling and seismic surveys

- Implement IoT infrastructure for preventative management

- Deploy real-time monitoring systems

- Utilize GPS technology and automation procedures

Environmental Considerations

- Implement dust suppression systems

- Use recycling and proper disposal of drilling fluids

- Protect groundwater and local ecosystems

- Comply with environmental regulations

Choosing Techniques for Different Rock Types

| Rock Type | Characteristics | Recommended Tools | Special Considerations |

|---|---|---|---|

| Granite (Igneous) | Very hard, abrasive | Diamond-encrusted drill bits | Requires strong, durable equipment |

| Limestone (Sedimentary) | Less abrasive, softer | Standard carbide bits | Control fracture lines to prevent breaks |

| Metamorphic rocks | Variable hardness | Assess individual characteristics | May require specialized approaches |

Equipment Maintenance

🔧 Maintenance Priorities

- Routine inspection and calibration of electronic and mechanical parts

- Proper lubrication to minimize wear

- Clear procedures for part replacement

- Remote oversight capabilities for early failure detection

- Regular maintenance logs and checklists

Post-Drilling Procedures and Cleanup

Immediate Post-Drilling Tasks

- Remove all drilling fluids and cuttings (mechanically or chemically)

- Implement real-time monitoring for cleanup verification

- Use automated cleaning technologies where available

- Apply predictive analytics to identify potential issues

Environmental Cleanup

- Focus on advanced cleaning technologies

- Implement proper waste management disposal

- Use brine reuse and transport analysis

- Minimize well drainage seepage

References

-

Petit Point Mini Perfume Bottle Brooch – University of Wisconsin Digital Collections – A detailed description of a unique mini perfume bottle brooch with intricate designs.

-

Rarities at Rennebohm Hall: Perfume Containers – University of Wisconsin – Highlights rare miniature perfume bottles, including a gold-mounted bloodstone scent bottle from the Louis XVI period.

Frequently Asked Questions (FAQ)

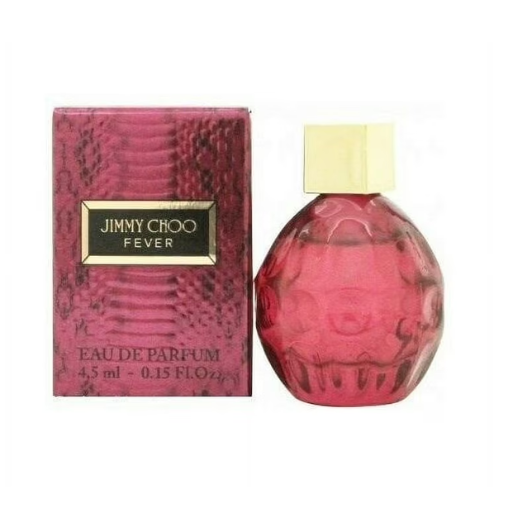

Is there such a thing as a mini perfume bottle?

The mini perfume bottle is essentially a smaller-sized perfume bottle, which is the norm in the 5-milliliter category. The small dimensions are, of course, very practical, especially if you need a travel perfume or something you can use on the run.

What are the main advantages of a mini refillable perfume?

Getting a mini refillable perfume makes it a piece of cake to bring that signature fragrance you love with you wherever you go. This is a very practical solution, as will not only give you an advantage in terms of managing your image, but it will also not leave a hole in your pocket, because you can easily, and quite often, refill it with your desired scent.

Which outlets stock mini perfume bottles?

You can easily get mini perfume bottles from various retailers, including online platforms like Amazon and brick-and-mortar beauty shops. It is essential to choose from a wide selection of stockist to get the retailer that provides travel kits that have made bottles as well as matching and leak-proof bags.

What do you stand to gain from using a refillable perfume bottle?

The benefit of using a refillable perfume bottle is that it is helpful in minimizing waste and the environmental toll of single-use bottles, as it allows you to carry favorite scents of your perfume. Often, the design of the refillable bottles is such that they are inherently portable and designed to not leak, which makes them perfect for travel.

Should one go for mini travel perfume atomizers?

Yes, mini atomizers that are designed for travel use for perfumes are of huge benefit when it comes to convenience. This is ideal for an individual who is in love with a fragrance and loves travelling. Such minis’ are easy to carry, lightweight, and, according to travel, are even available in a spray bottle, which makes it very easy to apply fragrance at any time.

How many milliliters are offered in the size options for mini perfume bottles?

Though it is possible to find various sizes in the market, the 5ml is particularly popular and of great help. It is the perfect size for sampling different types of fragrances and can be easily carried in daily purse or even in the travel bag of an individual.

What are the options available for purchasing sets of mini refillable perfume bottles?

Yes, from a number of different brands you can get sets of refillable mini perfume bottles which come in packs of four and above. This can be a great idea for people who want to have and carry different fragrance bottles and even share with friends.

What is the proper method for refilling a mini perfume bottle?

When refilling a mini perfume bottle, you may use a funnel or refillable mini spray to transfer the fragrance from the larger bottle with ease. Make sure to do your refilling when the contents of the refillable perfume spray are clean to avoid mixing of scents.

Is it possible to obtain designer-made mini perfume bottles?

Absolutely, several designer brands produce luxury mini bottles, offering a touch of class in a small quantity. These bottles are usually characterized by distinct, graceful shapes and are excellent options for collectors and as presents.